![]() Master Embroidery Skills

Master Embroidery Skills

![]() Create A Business Plan

Create A Business Plan

Get The Support You Need

Get The Support You Need

You don't have to do this on your own.

Online Training and Personalized Coaching to Help You Grow Your Embroidery Business!

Starting or growing an embroidery business can be hard. We can help.

Starting or growing an embroidery business can be hard. We can help. We simplify the business of embroidery into easy-to-understand lessons for the new embroiderer. My passion is to help get the new embroiderer off to a fast start and help the existing embroiderer improve their skills so that they can provide higher quality embroidery and increase their profitability! We Help Embroiderers Succeed!

Fast-track your embroidery skills from amateur to professional quickly.

Get the personalized coaching you need to build a business that thrives.

Implement proven business plans that have worked for others just like you.

Trusted by the world's most influential brands

(and fastest growing startups)

We don't just care about your business. We care about you.

Now more than ever, your business decisions matter. That's why I get frustrated when I see good people who love embroidery struggle to make money simply because they don't have the right business tools to work with.

But over the years, I've noticed things successful embroidered do that amateur embroiderers don't do. And I'd Like to teach you exactly what these things are.

Here's how it works.

Choose Your Path

Become a Member

Grow Your Business

Each online course and coaching session is customized to help you regardless of where you're at on your Embroidery Journey!

Once you start the path that's right for you, you'll immediately join a network of Embroiderers who will inspire you to do your best!

With the right tools in place, you'll have everything you need to start, grow and scale your Embroidery Business in no time at all!

Testimonials

I signed up for some training and very quickly decided that a Lifetime Membership would be a most valuable investment in my business. Her training is applicable to all varieties of machines and software and to embroiderers at all stages of experience.

I signed up for some training and very quickly decided that a Lifetime Membership would be a most valuable investment in my business. Her training is applicable to all varieties of machines and software and to embroiderers at all stages of experience.

Joyce provides the marketing, pricing, technical and artistic resources to resolve just about any problem. I know that whenever I am stuck or just plain curious I can access the online info or reach out via phone or email. Joyce is a generous and encouraging teacher. I have realized an increase in ability and confidence thanks to what I have learned.

Jeanne Fitzsimons

Owner, Fitzstitch Embroidery

Personal Coaching with Joyce gave me the confidence I was lacking. Her business management skills are perfect for the small and large embroidery shop. Her teaching style put me at ease and was very patient with me. The way Joyce broke things down into steps, made everything understandable and do-able, not overwhelming.

Personal Coaching with Joyce gave me the confidence I was lacking. Her business management skills are perfect for the small and large embroidery shop. Her teaching style put me at ease and was very patient with me. The way Joyce broke things down into steps, made everything understandable and do-able, not overwhelming.

I now have the tools to succeed with my business, not just pay my own bills. I am so glad I hired Joyce for my personal coach and will do so in the future if needed.

Laura Driesel

Owner, Aunt LuLu's Embroidery

We had been struggling financially and I want to thank you for all of your hard work and for the incredible amount of invaluable information you offer to a new or established embroiderers. I just had to drop you a quick line to let you know how thrilled I am having access to your How To Price Embroidery Program!

We had been struggling financially and I want to thank you for all of your hard work and for the incredible amount of invaluable information you offer to a new or established embroiderers. I just had to drop you a quick line to let you know how thrilled I am having access to your How To Price Embroidery Program!

Once you put your information into the base program, man, it creates your price list for you! It is a tremendous tool! The videos that explain the system really simplify the entire process. It is well worth the investment!

Cindy Proctor

Embroidery Business Owner,

Busy Bee Embroidery. Harrisburg, PA

Real Coaching

Our virtual business coaches are the best in the industry.

Real Commitment

If you're not completely satisfied, we'll give you 100% of your money back.

Real Results

Our methods are proven to get you the results you want.

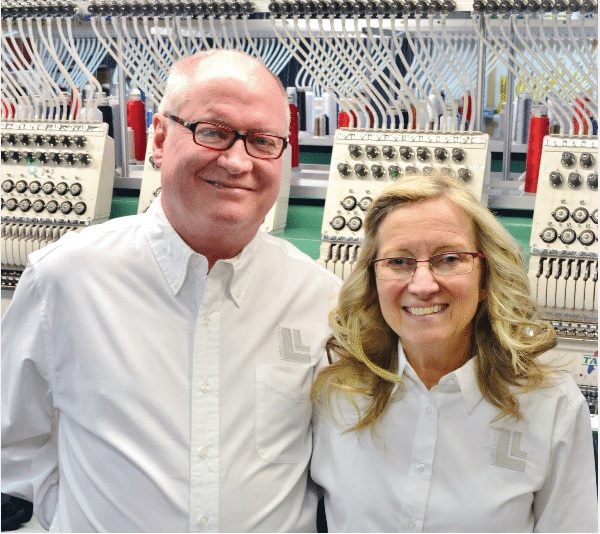

Work With a Renowned Embroidery Business Expert

We know you want to be able to make money in your embroidery business. In order for that to happen, you need to have the skills to build a successful embroidery business. The problem is that it's hard to know where to start which makes you feel overwhelmed. We know how overwhelming it can feel to start a business on your own. That's why we created an online coaching program that's used by some of the world's most influential brands and fastest-growing startups. We offer two paths that are designed to meet you exactly where you're at, no matter what stage of personal or business growth you're in. We'll help you and your team master everything there is to know about embroidery and business so that your business will thrive. Here are a few of the many benefits of my training program for embroidery business owners:

- Get access 24/7

- Learn at your own pace

- Real-time support

- Get one-on-one business coaching

- Customized lesson plans

- Receive personalized support

- Designed for offline training

- Same content as the online program

- Certification available

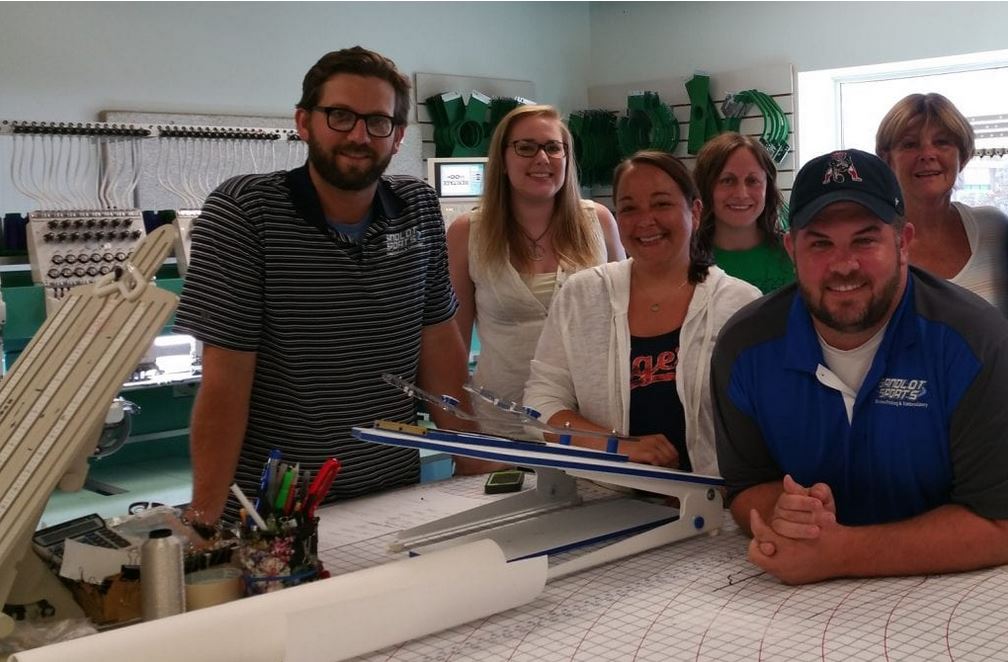

"Joyce's training was the most focused training that our company has ever seen...Her techniques and advice filled each embroiderer with confidence to get better at their craft."

Adam McCauley

Co-Owner, Sandlot Sports LLC

There Are Three Steps On Your Journey To Success:

- Choose Your Path: Each online course and coaching session is customized to help you regardless of where you're at on your Embroidery Journey!

- Become a Member: Once you start the path that's right for you, you'll immediately join a network of Embroiderers who will inspire you to do your best!

- Grow Your Business: With the right tools in place, you'll have everything you need to start, grow and scale your Embroidery Business in no time at all!

Get in Touch with an Embroidery Expert Today!

Are you looking to start an embroidery business? Then it would be best to rely on professional embroidery coaching. Learn from a qualified embroidery expert to teach you how to start a successful business. Get in touch with us by calling 607-427-1026, or by emailing our in-house expert. More information about our embroidery school can be found online.

How Would You Like To Know The 3 Skills To Master For A Successful

Embroidery Business?

Download your Copy TODAY!

Fill in your Name and Primary Email Address. I will send you "Embroidery Business Mastery" Today!

Don't struggle on your own.

Get the online support and coaching you need to build a successful embroidery business.