I go into many embroidery shops to do on-site training and I am totally amazed at the amount of spoilage that I see in boxes. These boxes of ruined garments are very costly to the business owner.

Learning how to control production spoilage in your embroidery business is an important step in reducing the total cost of operating your embroidery business. Operators should be required to show the amount of garments that were lost or ruined. This should be part of the production form that they are required to fill out at the end of each completed job. You must also know why the loss occurred. Keeping tracking the causes and the operators can help to reduce the loss and avoid them in the future.

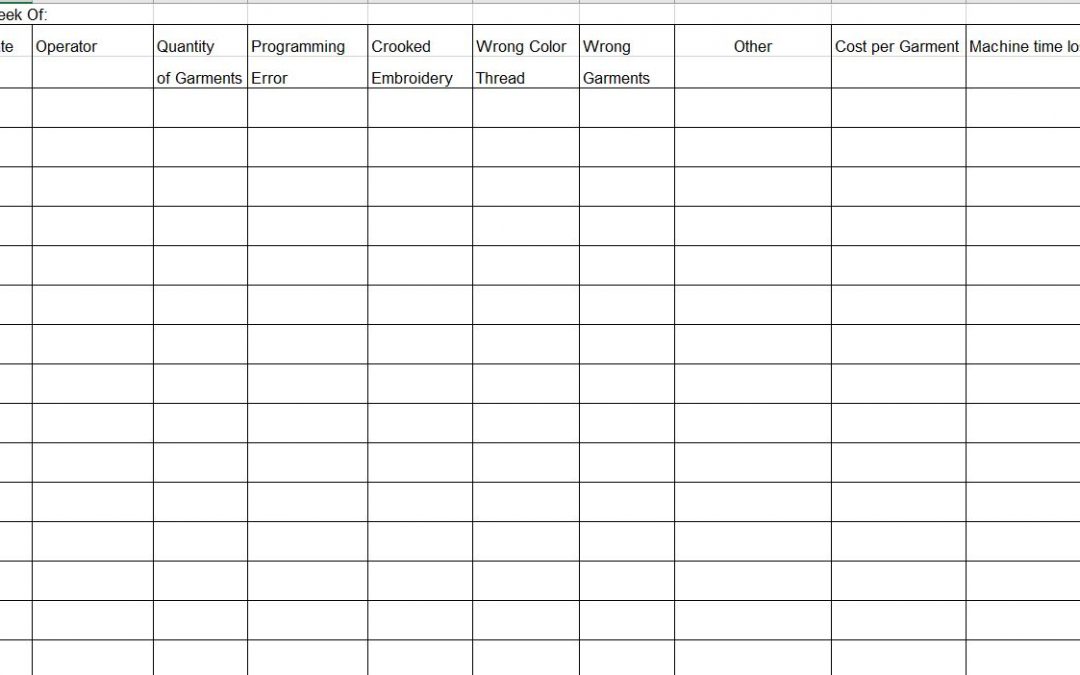

Keeping a chart on a weekly basis of these losses is very valuable. This information can be reviewed at the end of the week and used to help retrain the operators in the areas that they are apparently lacking information. When operators know that they are being tracked, they have a tendency to be more careful and pay closer attention to detail.

Many people say that this is part of your Production Cost! I do not agree with that at all. This is a cost that can be almost eliminated if the employees are trained to pay attention to all of the details. Yes, there is some spoilage when a person first starts to be trained, but they must be trained from the very beginning that this is not acceptable.

Embroidery Industry Standard of Loss

There has been an industry standard for many years of a 2% loss. Many claim that a 2% spoilage rate is acceptable. You may have that in your contract, but many people will not do business with you if you have a spoilage rate that high. If you properly train your operators to be aware of all of the factors that can happen and how to avoid them, your spoilage rate will be greatly reduced.

I created a simple Wastage and Spoilage Report that you can download, print out and use to keep track of the production spoilage in your embroidery business. Just fill in the form below and I will send you over the Spoilage Report. Even if you are a one person shop, this will help you keep track of the costs that your errors create. This is a huge eye opener to everyone!