Embroidery machine needles are one of the most important components of your embroidery. Having the correct knowledge about what to use for what type of fabrics is extremely important. How many times when you are getting ready to embroider an item do you ask yourself?

- I wonder if I should change this needle.

- What kind of needles should I use for the type of fabric I am working on?

- When do I use a sharp or ballpoint needles?

- What is the difference between the sharp and the ballpoint needles?

- How do I know what size needles to use?

- Do I need to use a special needle for caps

- Do I use a special needle for leather?

- What kind of a needle do I use for sheer fabrics?

- How often should I change my needles?

There are some hard and fast rules and a lot of opinions as to what needles you should use for different types of fabrics. I will tell you what I have found through my many years of experience and what works best for me and my business.

There are several kinds of needle sizes and systems, but the needles that I found that work the best for most of my general applications are the DBxK5 70/10 sharps and DBxK5 70/10 ballpoints.

Most machines arrive with 75/11 sharp or normal point needles and you are supposed to be ready to embroidery anything! Right!!!

The DBxK5 system is designed specifically for embroidery with a large elongated eye for the thread to slip through easily. Another system used for embroidery is the 16×257. This is basically the same needle except the eye is smaller, therefore, it is also a little stronger because of the smaller eye.

It is important to learn about the needles and understand why you would need to change them for the different types of embroidery and fabrics that you will be using.

Embroidery Machine Needle Systems

The systems used to determine the size of the needle are both European(metric) and the Singer (United States). The European system is designated by the metric size of the blade followed by the Singer system which uses a nominal number such as the 75(metric)/11(nominal number). The size of the needle is based on the width of the blade. The European designation is the width of the blade multiplied by 100. A needle that is .75 mm is a 75/11 needle. Both numbers are always used to designate the size and can be visibly seen with a magnifying glass on the shank.

If you will hold the needle in your hands and view it through a magnifying glass, roll it around in your finger until you see the number. Sometimes the metric number is on one side and the nominal number is on the other side. If it is a sharp or normal point, it usually shows the number only, if it is a ballpoint, it will have a B or BP or the size of the ballpoint such as SES(light ballpoint), SUK(medium ballpoint) or SKF(heavy ballpoint). If it is a medium ballpoint, depending on the brand, it may only have the B or BP following the number. Not all brands carry all of the different size points.

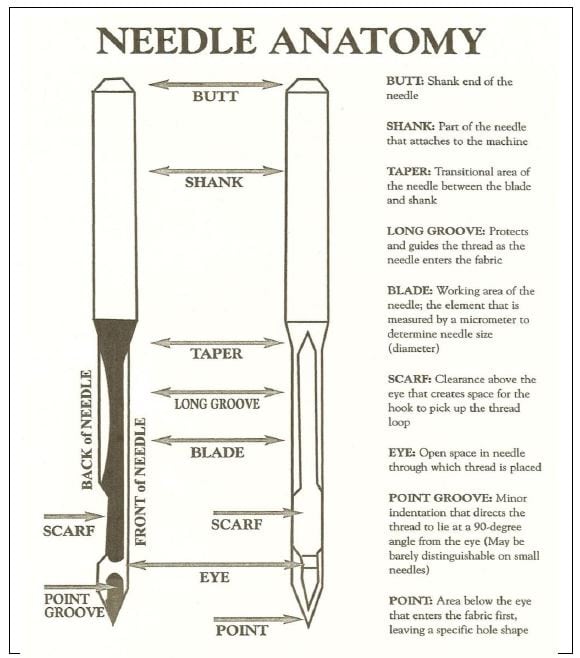

Following is a picture of the needle showing all of its parts with a view of the front and the back.

As a general rule, your sharp, or normal point needles are used for your woven fabrics with a few exceptions and your ballpoint needles are used for your knits and fine fabrics such as sheers. I have used with success 70/10 sharps on some knits but it is best to be safe and change your needle to the 70/10 ballpoints when you are working on knits.

If you have a lot of fine detail, the 70/10 needle will be a much better choice for the clarity in that detail. The finer the detail in your design, the smaller the needle you should be using. If you are embroidering lettering that is less than .20 inches or 4 mm. it would be best to use a 65/9 or a 60/8 needle. If you do decide to use either the 65/9 or 60/8 needle, you must also use 60 weight threads instead of 40 weight thread. Most of your embroidery is done with 40 weight thread. You have a limited color selection of 60 weight thread. If you have your designs digitized, you must let your digitizer know that you want to use this small needle and 60 weight thread. The smaller the needle, the smaller hole it will make in the garment and the sharper your finished image will be on your finished product.

When you are using 30 weight thread you will need to change your needle to a 80/12. Sometimes a 75/11 needle will work, but it can cause thread breaks because the eye of the needle is smaller and causes too much friction for the thread. The eye of the needle gets larger as your needle size increases.

The sharp needle actually has a round point on the end of it, but is sharper and more pointed than the ballpoint needle. It is made to penetrate the fabric wherever it goes. Sometimes when it does penetrate it will cut the fabric. If you are using it on a knit and it cuts the fibers, it can actually make a run in the knit. Sometimes this does not occur or show up until after it has been wash a few times. Sometimes it will cut the center part of small letters out, such as the center of o‚’s, a‚’s b,‚’s and etc. Again, this may not be noticed until after it has been washed.

The ballpoint needle has a small round ball on the end of it and is designed to penetrate between the fibers of the knit eliminating the chance of the cuts unless it is a dull needle. If it is dull, it will definitely cut the fabric and cause runs and holes. On knits, the smaller the needle point, the better your design will look when it is finished. The ballpoint needles come with light, medium and heavy points. The light ballpoints (SES) would be used for lightweight fine knits and sheer woven fabrics, such as silk.

If you are working on a 100% Pima cotton shirt, this would be your best choice. The medium ballpoints (SUK) are the most popular and used for your fleeces, t-shirts, sweatshirt fabrics, and heavier knit placket shirts. The heavy ballpoint (SKF) is used on heavy bulky sweaters and most types of elastics goods with the exception of spandex. I would use the light or medium ballpoint on spandex. This fabric is lightweight.

There are new moisture-wicking fabrics on the market that may be tough to work with. These fabrics are stretchy and very soft. The wrong needle will ruin them with the first stitch. If it is a knit fabric, you must use a 70/10 ballpoint needle for these fabrics in order to eliminate any holes in them. If it is a woven fabric that is still soft and stretchy, then you must use a 70/10 sharp needle. It is very important to know whether your moisture-wicking fabric is a woven fabric or a knit fabric.

Embroidering Machine Needles For Leather

To embroider on leather, you can use a 70/10 sharp, 75/11 sharp or a wedge needle made especially for leather. Your choice depends on the type of leather that you are going to embroider. If it is a soft leather, then your best choice is the 70/10 or 75/11 sharp needle. If it is a heavy type then you will need to use the wedge point needle. You will still want to use the smallest needle that will do the job.

The wedge point needle actually makes a slit in the leather for the thread to travel in. The best way to find out for sure which type of needle to use on your leather is to experiment. Go to a used clothing store such as the Salvation Army and look for the least expensive and the closest type of leather that you will need for your project and work with it. Use both types of needles and see which one will work the best for your type of leather. These wedge point needles are also ideal for heavy vinyl.

Embroidering Machine Needles For Metallic Thread

When you are using metallic thread, the correct needle to use is the DBx7ST. This needle is identical to the DBxK5 except the eye is elongated and rectangular in shape so that the metallic thread will pass through it easily.

If you are going to use a heavy twisted thread then the correct needle to choose is the DBx9ST. The eye is this needle is twice the size of the eye in the DBxK5 needles. The twisted threads that I have used required a 90/14 needle.

Embroidery Machine Needles For Coated Fabrics

Needles are available with coatings on them. They are known as Teflon coated or Cool Sew needles. They are especially helpful if you are using a synthetic such as Cordura Nylon, or a sticky backed fabric, or a heat seal backed fabric such as athletic twill. They help to reduce friction.

Titanium Needles

A stronger Titanium needle is also available. The points on the titanium needle last longer than the other needles, as much as 5 times longer. They are a bit more expensive, but the amount of down time to change needles is also greatly reduced. These needles are highly recommended if you experience a lot of needle breaks due to high speed or if you do a lot of caps. In some of the high speed productions shops that I have been in, they use nothing but Titanium needles for this reason. I too use a Titanium needle for all of my caps. I have found that the 70/10PD in Titanium is great for most of my cap applications. Sometimes it is necessary to change to an 75/11 needle for the plastic mesh back caps. The PD signifies that it is Titanium.

When To Change Your Embroidery Machine Needles

Some people say that the needles need to be changed about every 2 million stitches, some say 1 million stitches or 8 consecutive hours of sewing. A lot of this depends on the speed of the machine, the type of fabric and backing that you are using and how many times you have actually run that particular needle bar. Sometimes this is very hard to calculate. I have found that if I am running a large job on the same needle for several days, it is a good idea to check them at least once every couple of days.

I use a 10 times power linen tester to check my needles. This is a small magnifying glass that can detect the smallest scratch on the eye of the needle and you can actually see if the tip is broken. It is a great tool for this application and is a good investment. They are not always easy to find, but I did order one on the Internet and have found it extremely valuable.

You want to make sure that all of your needles are changed during your monthly maintenance. If you do not change your needles any other time, make sure that you schedule the needle change along with your overall monthly maintenance.

It is a great idea to have a variety of needles on hand to test and see what works for your needs and requirements and then make sure that you know where they are if you have a combination of them in your embroidery machine.

Keeping Track Of Your Embroidery Machine Needle Changes

Many shops will have a combination of sharp and ballpoint needles in their machine, but you need a system in order to keep track of them. I created a Needle Replacement Sheet that I use constantly. Every time I change a needle, I write it on this sheet and I have it taped to the back portion of my machine. I write in the size and type of the needle and the date that I changed it. This is very important. You don‚’t want to embroider a fine golf shirt with an 80/12 sharp needle. You will have a massive amount of holes. Don‚’t think that you will remember where you put those needles, this just does not happen in the real world. You must have a good system to keep track of them.

You will find the Needle Replacement Sheet in the Machine Maintenance section of the Embroidery Business Academy members area.