Do you ever see with holes in garments after embroidery? Do you know how to prevent holes in garments from embroidery? Once the holes are there, it is very hard to repair them, sometimes impossible. Yes, many times this can be done, but the time that it takes is very costly. The best course of action is to prevent them from occurring in the first place.

If you see holes in garments after embroidery, check to see if any of these have been the culprit.

- The wrong type of needle

- The wrong sized needle

- A burr on the needle

- Too many stitches in your design

- Too many stitches in one area in your design

- The wrong type of backing

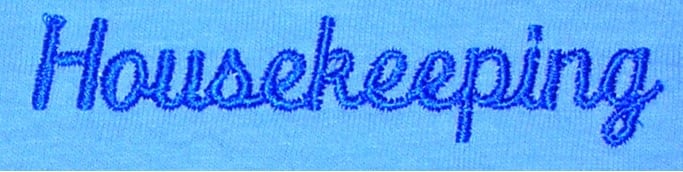

In our featured image, there are holes inside some of the small letters. These holes were created because the wrong needle was used. This image of embroidery was taken from a lightweight cotton t-shirt using polyester thread. The needle that was used was a 75/11 sharp needle. On a knit garment, you should be using a 70/10 ball point needle. As far as backing or stabilizer is concerned, on a knit garment, use 2 layers of no-show and1 layer of crisp tearaway backing along with topping on the top. The no-show cutaway backing holds it firm and gives it great stability and the tearaway keeps the small lettering crisp and flat so that it does not pucker up. This is especially important when you are working on a performance fabric.

Many times you will see holes in the centers of small letters when there are too many stitches in one area such as going around a curve. If you decrease your density this will usually help. If it does not cover enough, increase your underlay stitching, not your top thread stitching.

Holes in garments after embroidery can be totally avoided. I have a checklist that you can get to use as you are sewing out each of your designs before applying them to the finished garments. This checklist is going to help you with many of your production issues!