Preventing possible issues with production runs is essential when planning your daily embroidery production. Trying to get the best production possible out of every single day is a must if you want a profitable embroidery business!

In today’s economy, where so many embroidery business owners are doing all they can to keep expenses down with less employees, this is extremely important.

You always sew out all of your embroidery designs before you start any new jobs. Right!! Paying close attention to every detail of a logo is important when you are trying to prevent errors before starting a long production run! You want to thoroughly examine your design as it is stitching to see if there are any issues you need to correct or improve on.

You must watch the machine as it is sewing out your design in order to be able to pinpoint any of the possible problems! You cannot start the machine and walk away then expect to be able to find the issues, it just does not work. YOU MUST watch it as it sews out! As it is sewing out, ask yourself these questions:

- Is there something that you can do to shorten your run time?

- Are there any thread breaks? If so, find out why. Maybe your density is too heavy. Check for a dull needle, bad thread, or tension that is too tight.

- Is it locking as it starts and stops? If it does not lock at the beginning, the thread can come out of the needle. This can cause a real production nightmare! No lock at the end, the thread can unravel.

- Is it trimming where it is supposed to?

- Do I see any threads between my letters? If you do, they are not close enough.

- If I change my running order of my text will it run faster? First line left to right, second line right to left, third line left to right.

- Are all of the colors correct and are my colors running in the correct order?

- Do your letters or columns look to thick or too thin? Your letters may be pushing because your density is too heavy or your pull comp is too heavy. If too thin, your pull comp needs to be increased.

Check your sew out and have it verified before the job is started. Make sure that you watch each stitch as you sew out the design to see if there are any mistakes or problems that can be prevented. Slowing the machine speed down can help you pinpoint any issues.

- Do you have any jump stitches that are too long? This can cause the thread to get caught and your needle to break.

- Are all of your starts and stops in the correct location? If not, your machine has to move too far to start the next sequence causing wasted production time.

- Is your sew sequence in the right order? You do not want any travel stitches showing. A wrong sew sequence can create too many trims that could have been prevented if the sew sequence was changed.

- Can any of your color changes be combined? This will depend on how your design was created and what it is going to be sewn on. Sometimes like colors can be combined if your design is going to be sewn onto a flat garment. I do not recommend doing this for embroidery on caps. Please note: This can cause registration problems. Before you take this step, make sure that you can combine the colors and not have any registration issues.

It does not matter if you digitized your embroidery design or had the best digitizer out there doing your work, make sure that you sew out every design before you start the job and watch it sew out stitch by stitch. Not only will you prevent issues; you can also learn from watching your designs sew out. This is also true if you have set up a design or lettering in your software. Every design is a new design, digitized or not, and needs to have the same close attention to detail.

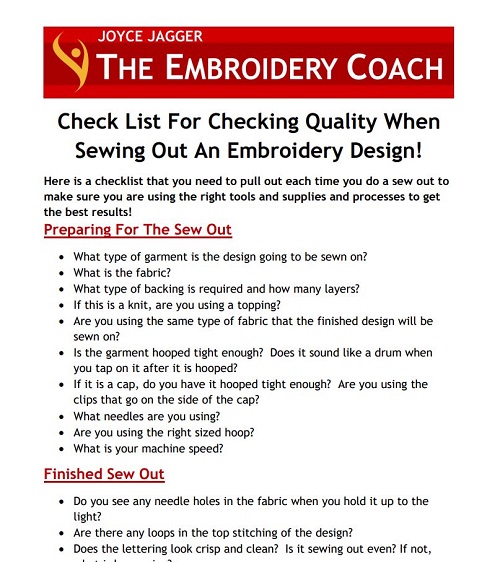

Create a checklist of all of the items to look out for as you are doing your sew outs and go right down that checklist to make sure that you have covered every item. This is going to help you save a lot of time and frustration as you are going through your long production runs.

There is nothing any more frustrating than having constant thread breaks or knowing that something could have been changed in your design to make the entire job get done in a lot less time! Time is precious and time is money! You cannot get it back once you have lost it!

It may seem like a waste of your time to watch designs sew out but it never is. I have been digitizing for many years and planning out production for many more years. I never send out a design to production unless I have sewn it out at least once to make sure that it has no issues, and yes, I watch it! Preventing unnecessary production issues is part of planning for all your embroidery production runs. This is going to help you create more profit in your bottom line!

Would you like a copy of the same checklist I use while sewing out each design? We will be happy to send it to you. You can pick one up for free by filling out this form.