by The Embroidery Coach | | Embroidery Business Marketing

Building great relationships with your customers is one of the most important duties that we have as business owners and this is something that does not have to cost a lot of money. There are three ways of building great relationships with your customers and prospects, relationships that will help you build up a base of loyal repeat customers.

- Personally connecting with your current customers

- Email Marketing

- Make sure you are offering Excellent Customer Service!

Many times it is the little unexpected things that we do that mean the most and keep that customer coming back to our business over and over!

A handwritten thank you note when you have done a large job for a customer, thanking him for his business and telling him how much you appreciate the fact that he trusted you with his order! Another time to send a thank you note is when you meet someone new at a networking meeting.

These are both great strategies in showing your appreciation and building a new relationship or improving a relationship that you want to see grow even more.

Connect With Your Customers To Build Great Relationships!

The best way to start building great relationships with your customers is to connect with each one of your current and lost customers. Start out by making 3 lists.

- Current High Volume Customers

- Current Lower Volume But Repeat Customers

- Former or Lost Customers

Create some scripts that will make it easier for you to talk to people. I have found that having the scripts in front of me, it just made it easier as I was talking to them and I did not forget anything. You can also print out a script for each customer and fill in the blanks as you are talking to them. This was always my favorite way of working with my customers on the phone. I still do this today. Keeping notes makes it a lot easier to recall what they said for future reference.

Call each one of your customers- Start with your current high-volume customers – Ask them questions such as:

“What is it that you like about our products or services? In your opinion, what it is that I can do to improve my company or service to you? Do you have a particular time of year that works best for you that we could sit down and plan out some promotions for you?”

If it is a customer that you are no longer working with, you will ask them different questions such as:

“I know that you are no longer using us as your supplier for your gift items and promotional products. Is there a way that we can change that? If you don’t mind my asking, what was it that I did or did not do that made you decide to go elsewhere?”

As you are talking to them, tell them about your referral program and how it works.

After you finish talking to each customer, fill out a thank you note, thanking them for taking the time to talk to you, and insert some business cards. Make sure that you tell them to sign the back of the business cards before they hand them out to their family, friends, and acquaintances. This handwritten Thank You note will go a long way in helping to build your new customer relationship with that customer and it will be something that they will not forget!

Getting your customer’s opinions and feedback is extremely valuable to your business and makes it a lot easier to plan your strategies as to how to work with them and provide them with the type of services and products that they will be anxious to purchase from you. They really do appreciate you asking them what they need. This can be the beginning of a long working relationship with each one of your customers.

‘If you don’t have any kind of relationship with a customer, they’re simply not going to be a customer, says Brent Leary, a columnist for Inc. Technology and the co-founder and partner of CRM Solutions, LLC., based in Stockbridge, Georgia. ‘If we can build a relationship where they know who we are, they like what we can do, and give an example of how we can help them, then we can give them the trust and that helps solidify relationships.’

This is part of the Embroidery Business Marketing System program that I am teaching. Click Here to get signed up for it. I have a lot of great information for you!

by The Embroidery Coach | | Embroidery Business Marketing

When I first started my embroidery business, I thought that all I had to do was put out my sign to let everyone know that I was now in business! I soon found out that getting customers was not as easy as I had envisioned. I really loved what I did, but I had no plan in place to attract new customers. This is not the right way to get your business started! I learned very quickly that a Marketing Plan was essential for my embroidery business and I needed to have a plan in place for every aspect of my business!

What is Marketing?

Marketing in my own simple terms is All of the things that you do to get your product in the hands of the right people! It is also all of the ways that you do to get the word out about your product or service.

The most important process in getting ready to market your embroidery business is to create a working plan. A working Marketing Plan is essential and you want one that will help keep you on the right track. If one strategy is not working, you can go back and review your plan and make some changes, but without a working plan you spend your time running in circles and do not have any idea as to what to do or where to get started.

The Starting Point For Your Marketing Plan!

You need to create a simple picture of your next 12 months. By that I mean what is going on around you in the next 12 months. What are the holidays, special happenings, the different times in a persons life that they need gift items, school sport seasons, and corporate events that take place in your area. These are just a few of the areas that you can cover. Make a list for each type of event.

- Do you have a Niche Market?

- List the events that are held throughout the year.

- What type of items are needed for each one?

- What months do each of these happen?

Write down each month that these events are happening in. You can plan special promotions around each one? This is the beginning of your plan.

In this economy today we have to be very proactive and not sit and wait for the next customer to walk in the door. It is not going to happen! There are too many choices for them and we have to make sure that we are in their mind first and foremost so that they will think of us instead of the competition when they need our services. Without an actual working plan it is very hard to be proactive.

People need you and what you have to offer. All you have to do is make them aware of what you have, work with them to find out exactly what they are look for and you can create the perfect relationship.

Once I put a Marketing Plan together and started working my plan, I found out that letting everyone know that I was in business was not as hard as I thought it was going to be.

If you do not have a Marketing Plan written out, take the time to get it started today. This is extremely important! Without a Marketing Plan it is very hard to grow your business and keep yourself on track!

Click Here to help you get started creating your own Embroidery Marketing Plan today!

by The Embroidery Coach | | Embroidery Production

Do you feel like your Embroidery Production Spoilage is getting out of hand? Are you having an unusual amount of rejects or mistakes being made during the production process? Do you have a lot of returns or customer complaints? Are you having to spend unneeded time redoing jobs because of misunderstanding?

In a small business these mistakes may be done by you as a business owner or one of your employees. In a large business, it is definitely being done by the person that is performing the task or doing the job. It does not matter who is responsible, but this is a problem that needs to be addressed immediately so that it does not get out of hand.

It is extremely frustrating when the customers start complaining about the quality or returning their items. Not only is this disheartening, it is very time consuming and hard on the bottom line. After working with many embroidery companies I have discovered this is becoming a growing problem among embroidery business both large and small.

Factors That Contribute To Embroidery Production Spoilage

There are several factors that can contribute to this but the top 3 factors are:

- Work Orders not written up correctly

- Missing information, lack of details or wrong information on the Work Orders

- Employees not trained properly

Other factors that can also contribute to embroidery production spoilage; especially in larger businesses:

- Lack of the right tools to work with

- Employees not paying attention to detail.

- Employees that do not take pride in their work

- Unpleasant working conditions

I want to talk about the first 3 factors and how to avoid them.

Work Orders not written up correctly, missing information and lack of detail sort of all rolls into one, but this is usually the number one reason that mistakes are made in the first place. Each work order should be gone over thoroughly to make sure that all of the information is correct along with all of the detail.

I have worked with embroidery companies that did not even have an image of the design on the work order. This was absolutely shocking to me! This is such a necessary item. If the operator does not have a picture of the correct design right in front of her or him, how can they be 100% sure that the right design is going to be embroidered on the correct products.

If the order taker mistypes the design number, this can cause a huge mistake. If a picture or an image of the design is in front of them, this can act as a double check to make sure the design is in fact the correct one. Also make sure that the color number and color names are written for each part of the design. If they are not, this too could be a problem.

You must be very explicit in the way that you give all of your information to the person that is going to be doing the job, and this means every part of the job. The more information they have, the better chance you have of getting the order right.

This is true for the single person business that is doing all of their own work. DO NOT depend that you are going to remember everything that the customer tells you and not have it written down. This just does not work! I have worked with a lot of people that say they do not need to write it all down; it is in their head and they will remember it. This may be true, but as you grow and add other people to your company, this does not work. YOU MUST make sure that all of your information about every part of the job is totally clear and that anyone could pick up that order and understand what needs to be done.

Employees not trained properly is a huge factor is mistakes being made and poor workmanship. You need to have a regular training program that you have either developed or purchased to start your employee training. Employees need to know what is expected, what a great product looks like, what a bad product looks like as well as each process that goes with their job description. They need to be fully trained in each one of the processes.

Too many times they are told once how to do something and then they are expected to go out and do what it is they were told to do. In one large company that I worked with they put their new operator on a single head for the first 2 weeks and started them right out doing orders right on the machine. There is no preparation beforehand, no training as to what backings to use for each type of fabric and anything. After a couple of weeks, they were put on a multi-head machine and they are basically expected to do any of the orders that came in and know what to use for the backings and other tools needed.

This is not enough training. I would never leave a new employee on a machine by themselves for at least 3 months. There are too many questions, too many variables and too many issues that can creep up. They need constant supervision for at least 3 months in order for them to build up the confidence that they need to do the job right.

Embroidery Industry Standard of Loss

There has been an industry standard for many years of a 2% loss. Many claim that a 2% spoilage rate is acceptable. You may have that in your contract, but many people will not do business with you if you have a spoilage rate that high. If you properly train your operators to be aware of all of the factors that can happen and how to avoid them, your spoilage rate will be greatly reduced.

Operators should be required to show the amount of garments that were lost or ruined. This should be part of the production form that they are required to fill out at the end of each completed job. You must also know why the loss occurred. Keeping tracking the causes and the operators can help to reduce the loss and avoid them in the future.

Keeping a chart on a weekly basis of these losses is very valuable. This information can be reviewed at the end of the week and used to help retrain the operators in the areas that they are apparently lacking information. When operators know that they are being tracked, they have a tendency to be more careful and pay closer attention to detail.

Many people say that this is part of your Production Cost! I do not agree with that at all. This is a cost that can be almost eliminated if the employees are trained to pay attention to all of the details. Yes, there is some spoilage when a person first starts to be trained, but they must be trained from the very beginning that this is not acceptable.

I created a simple Embroidery-Production-Spoilage-Report that you can download, print out and use to keep track of the embroidery production spoilage in your embroidery shop. Just click on the blue link and the .pdf file will open up for you. Even if you are a one person shop, this will help you keep track of the costs that you errors create. This is a huge eye opener to everyone!

by The Embroidery Coach | | Embroidery Business Marketing

Are you afraid of doing embroidery on caps? Do you put it off because you are unsure of exactly how to do it? Do you refuse to work on caps because they feel intimidating? If you feel like that, I can surely understand this. I was so afraid of caps when I first started my embroidery business. I absolutely turned down every job for caps, from anyone that wanted embroidery on caps or even brought them to me. This was like a foreign country and it absolutely scared me to death!

One day I had a customer come in and was desperate for one single cap and I decided to give it a try. Now back in those days, I did not have a cap machine and I would embroider on unfinished cap fronts and then send them to the cap manufacturer to have the cap fronts made into finished caps. That was simple and I did not have to deal with the blank caps. This was before they even made cap machines. When my customer only needed this one cap, I knew that I would have to embroider it flat but I was totally unsure of how to do this. I decided that I would treat it like any other item that I could not hoop and glued it down to backing that I had hooped. It worked and my customer was happy!

They have cap frames now that you can use to embroider fronts flat that holds the bill down. They are mainly made for the home machines that do not have the cap frames for them.

Once I got over the fear of that one cap, I started taking cap orders for finished caps and it was not nearly as hard as I had envisioned! I am so glad that I took that chance to overcome my fear of even trying to do embroidery on caps.

I then decided to purchase a 15 head tubular machine that I could easily use to do embroidery on caps and started taking cap orders on a regular basis. The next trick was to learn how to hoop them correctly and tight enough so that they would be straight and the embroidery would look great!

Here are some tips that will make it easier for you to cope with the embroidery on caps and help with taking the guesswork out of it.

- On structured caps, (6 panel caps with a heavy buckram lining in the front) steam press them first. This softens up the front of the cap, presses it flat and helps it to sit tighter on the throat plate of the machine. You can do this with a regular household iron.

- Use a 3 oz. tearaway backing that has been designed for caps. This is important. If it is a lighter weight backing it will not give you as good a registration. Sometimes you need 2 layers of backing to hold it closer to the throat plate.

- I always use a 70/10 sharp needle, but if you have needle breaks, switch to a 75/100 needle. Some people recommend 80/12 but I have never used this large of a needle on my caps. You cannot get the fine detail in the designs using an 80/12 needle. I use the 70/10 needles even on FlexFit caps.

- For best results, keep your design at 2.10 inches or less in height. This will allow for a design that can be embroidered on most caps. If it is an low profile cap or an unstructured cap (not buckram or lining behind the front fabric of the cap) then you may need to keep your design to a maximum of 2 inches in height.

- Make sure that you have the caps hooped tight and that you are using the clips on the side of the caps to hold it down. Place the clips at the bottom of the posts closer to the bottom of the cap. This will hold it in place but it will not distort the design at the top of the cap.

- Make sure your designs are starting from the bottom up and from the center out. If you are having your designs digitized, make sure that you tell the digitizer that it is for a cap and you need to have it start at the bottom and from the center out.

- Make sure that you have ample underlay to anchor your cap backing to the cap front to keep good registration.

- If you are embroidering a 2 color letter, embroider the inside first and then the outside of the letter before going on to the next letter.

- If you have a large fill area in the center, run a zigzag stitch up the center of the cap before actually starting the design. Tell your digitizer to do this if you cannot. This will help to anchor the design and keep it from pushing and pleating the fabric in the center.

- Start your design on half to three-quarters of an inch up from the metal strap that goes across the front and is sitting on the bill of the cap. If you have a short design, move it up to be in the center of the cap. If it is a tall design, then start it at the one half inch point up from the strap.

When you can learn to embroider on caps and do them efficiently, they will be one of your biggest money makers! Embroidery on caps is a constantly growing business and you do not want to miss out on this huge money making opportunity!

For more information on “How To Embroider On Caps” and other programs to help you grow your embroidery business, click here!

by The Embroidery Coach | | Embroidery Business Marketing

We all want fast! We all want the jobs to fly in the door and fly out the door with as little effort as possible! While that sounds like a dream scenario there are some very small steps that you can take that will increase your production in your Embroidery Business is a huge way! Here are 9 tips that will help you increase your production drastically!

- Keep your machine clean and maintained daily and you will have fewer issues, less down times and fewer tech costs. You need to clean out the bobbin area every single morning and oil it. You need to oil it again at noon or after every 4 hours of running time. This will help you keep your machine in tip top shape with far less downtime. Your production time alone will increase through this daily habit.

- Set up sharp needles on half of your machine and set up the other half of the machine with ball point needles. This will save you a lot of time when you have to switch from knits to woven fabrics. It is much faster to change a cone of thread than to change a needle!

- Keep the colors of thread closest to each other for your thread changes in your design. Example: If the design has 3 colors, place the 3 colors next to each other so that the machine will have less travel time from one needle to the next as it changes colors.

- Time all of the steps in each of your processes. Keep track of these times and try to better your best at all times. Encourage your employees to do the same. Maybe an incentive will help to make them move a little quicker with each step.

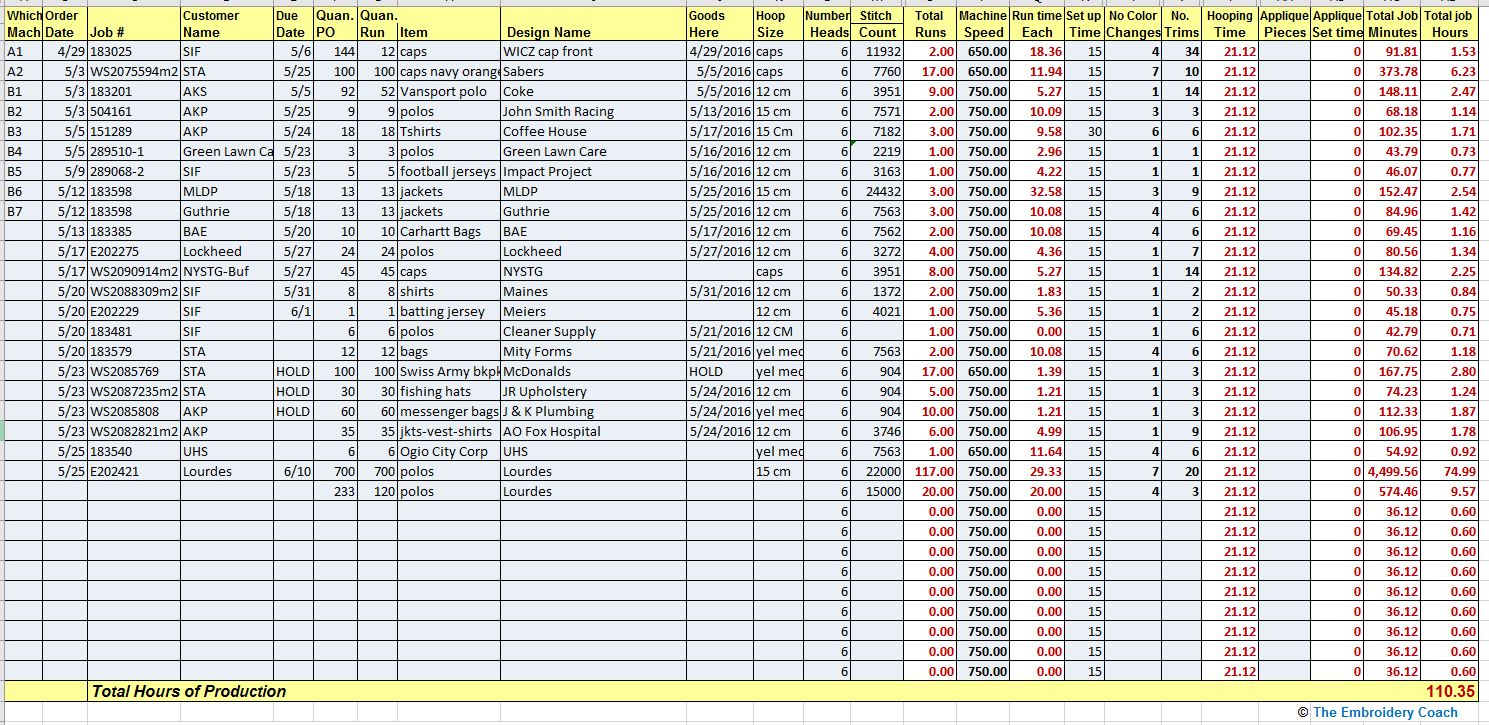

- Add the job to the schedule or tracking sheet as soon as it arrives or the order is taken. You may not have all of the information to complete the job at that time, but it needs to be logged in and kept track of immediately!

- When each step of the job is completed, add that to the tracking sheet to see the progress.

- When you have all of your information and the job is ready for production, assign the jobs to certain machines and put the schedule on the machine where the work will be completed. This schedule should be created the night before the job is to be run and the schedule should be placed on the machine that it is assigned to.

- Pay attention to the time that it is taking your operators to do the job. If your schedule is formatted correctly, the time allotted for the job will be right on the schedule. Make sure that it is being completed during that time frame. Employees seem to move faster when they know that they are on a schedule and are being timed.

- Plan your production so that you are running like kind jobs. If you have your machines set up for caps, run all of your cap jobs at one time instead of breaking down the machine for each individual order. Plan 1 day a week for caps and stick with it unless you do not have any caps for that week. Do not plan by date order. Plan it by type of products, hoop size and colors that you have on the machine at the time.

Following these tips will give you the fastest way to increase production in your embroidery business and you will be able to get more products out in a weeks‚ time using this method. More products out each week, more money in! This can greatly increase your monthly bottom line!

I have developed a simple and complete Embroidery Production Tracking & Scheduling Form‚ that will help you to keep track of each step of your production and give you the time that it should be completed in. This form is part of the How To Price Embroidery Program and will soon be available as a stand-alone product. It is a simple form for you to use and will help you to keep total track of your embroidery that is all formatted and will automatically figure the time that it should take for each job!