by The Embroidery Coach | | Embroidery Business Planning, Embroidery Production, Organizing

In Part 1 of our Saving Time series I talked about how to save time Creating Embroidery Design Layout Style Sheets, in Part 2 I talked about Limiting Your Embroidery Lettering Styles and in Part 3 it was about creating Sample tags for all of your showroom embroidered product samples. Today I am going to go over how to create an Organized Ordering System.

An Organized Ordering System

An organized ordering system is simple to put into place. This is true when you have all of your information computerized and even if you are using paper forms to be filled out while you are waiting on the customer. You can create Sales Order Packets with all of your forms included so that you do not have to look for your information forms while you are working with your customer. Inside of this Sales Order Packet you should have:

- Customers Quote form

- Your Order Form

- Form of Payment

- Production Timing Form

- Artwork Production form

- Packing slip.

When you are first working with a customer, they usually want a quote before they place an order. Prepare your customers quote and make a copy of the quote form for him to take with him. Place your copy along with all of the other forms into a file marked Customer Quotes. When the customer comes back to place his order, pull the packet of forms from the quote file and you are ready to complete your order taking process.

By having all of these forms together in one packet, you will keep all of the customer information together and you will prevent mistakes from occurring.

During this series we have gone over 4 ways to help your customers make quick ordering decisions. You want the order process to be a pleasant experience for both you and the customer. When you offer your customers so many options they only get confused and it takes longer for them to make a final decision and sometimes that final decision is no decision. Reducing the amount of choices you have to offer will save you and the customer a lot of time.

I hope that this series has helped you to become a little more organized in your ordering process and that you see the value of taking the time to go through your ordering process and make some immediate changes that will benefit both you and the customer!

All of these forms plus many more business and production forms are available through my Embroidery Business Training membership website, the Embroidery Business Academy.

Joyce Jagger

The Embroidery Coach

by The Embroidery Coach | | Embroidery Business Planning, Embroidery Production, Organizing

In Part 1 of our Saving Time series, I talked about how to save time Creating Embroidery Design Layout Style Sheets. In Part 2 I talked about Limiting Your Embroidery Lettering Styles. Today I am going to talk about saving time by Creating Sample Tags with order information to apply to all of your showroom samples.

Sample Tags With Order Information

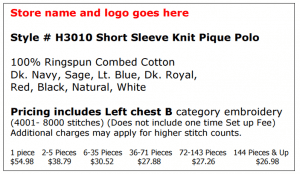

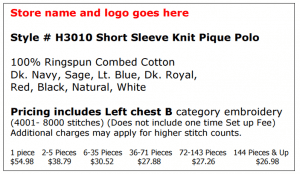

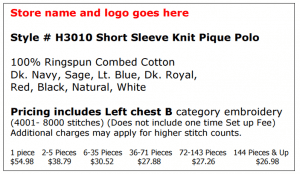

Your showroom should be complete with high-quality embroidery samples that are tagged with all of the order information that is applicable to that product sample. This tag should include the style number, colors and sizes available, manufacturer, price, and quantity pricing. All of this information should be on a Tag that is attached to the sample garment.

Your showroom should be complete with high-quality embroidery samples that are tagged with all of the order information that is applicable to that product sample. This tag should include the style number, colors and sizes available, manufacturer, price, and quantity pricing. All of this information should be on a Tag that is attached to the sample garment.

These embroidery Sample tags are very simple to produce and portray a good image to the customer about your organization. I created my Sample tags on card stock that I purchased from the office supply store, cut them apart, and laminated them. They stay very clean and always look professional when they are laminated. I then attached them with a Hang Tag attachment.

Having all of your samples tagged ahead of time with the appropriate information will save you a lot of time and prevent you from having to look up the information in the catalogs. As your pricing changes, so do your Sample tags. Always keep them up to date with all of the correct product and ordering information!

In part 4 of our Time-Saving series, I will talk about having an organized ordering system!

Joyce Jagger

The Embroidery Coach

by The Embroidery Coach | | Embroidery Business Planning, Embroidery Production, Organizing

In Part 1 of Saving Time-Helping Customers Make Quick Ordering Decisions, I talked about how to Create several Design Layouts Options for your customer to choose from. During Part 2 I am going to talk about limiting your customers lettering style options.

Limited Embroidery Lettering Style Options

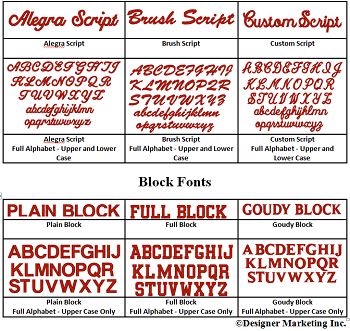

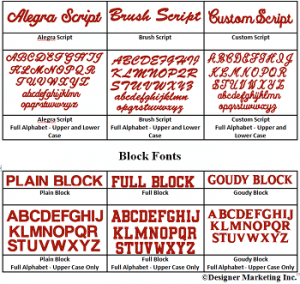

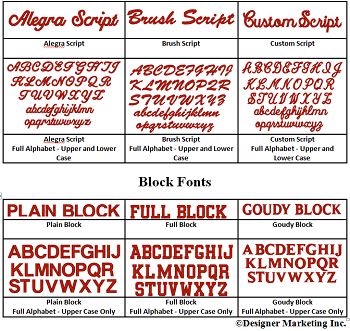

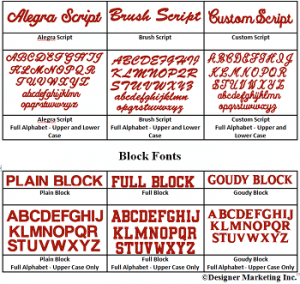

In each of the embroidery software packages today you have many lettering styles to choose from and it is very tempting to want to show our customers all of the lettering styles that we have available. Many new embroiderers make the mistake of offering all of these styles to their customers and letting them chose which one they want to use.

In order to do this, you must sew out every embroidery font that you have available and know what the capability and size restrictions are for each one. This takes a lot of time and is totally unnecessary. Our customers get so confused when they are faced with so many choices. I have found that the best way to handle this is to offer 2 or 3 Block lettering styles and 2 or 3 Script lettering styles. This is enough for them to choose from and will prevent the customer from being overwhelmed with your vast selection.

In order to do this, you must sew out every embroidery font that you have available and know what the capability and size restrictions are for each one. This takes a lot of time and is totally unnecessary. Our customers get so confused when they are faced with so many choices. I have found that the best way to handle this is to offer 2 or 3 Block lettering styles and 2 or 3 Script lettering styles. This is enough for them to choose from and will prevent the customer from being overwhelmed with your vast selection.

By limiting the embroidery lettering style options, you not only save time working with your customer in their selection, but you also save time in the set up of your lettering designs. If you are only working with a few lettering style options, you can have templates made ahead of time with all of the style settings included in the template. This is a huge time saving process when you are creating your customers design set ups!

In our next Saving Time series, I am going to talk about tagging your samples with the correct ordering information!

Joyce Jagger

The Embroidery Coach

by The Embroidery Coach | | Organizing

In Part 1 of Organizing Your Embroidery Business, I talked about organizing the information that you use in running your embroidery business. In Part 2 I l talked about your customer's design information. In Part 3 I talked about your Production process. In Part 4, I will go over the information for Shipping and Invoicing

The completed order, customer order form, and production form go to shipping. The shipping information is added to the production form. This shipping information includes the weights of boxes, shipping costs, and the time allowed for this process. The packing slip is filled out with all of the items listed that are being shipped to the customer. A copy is then made of the packing slip and attached to the production form and customer's order. These forms are all sent to billing.

The person doing the invoicing pulls the original customer order and uses the production form to do the invoicing. The production form is then detached and goes back to the production supervisor to be analyzed and to see what could or should have been done or what other methods could be used to save time and money.

These forms are very important. The original customer order is attached to the invoice created and filed in the accounts receivable drawer. After payment has been received, the paperwork is then filed in a paid file drawer or cabinet inside of the customer's file by order number or date.

Organization is not hard, but it does take some time and thought. You need to go through each process of your particular business and put an organization plan together. If you take the time to get fully organized, staying organized is very simple and you will save time in your total business operation.

I hope that this series on Organizing Your Embroidery Business has been helpful. I would like to hear from you about any areas of your business that are troublesome for you to organize.

Joyce Jagger

The Embroidery Coach

by The Embroidery Coach | | Organizing

In Part 1 of Organizing Your Embroidery Business, I talked about organizing your information that you use in running your embroidery business. In Part 2 I l talked about your customers design information. In Part 3 I am going to talk about your Production process.

The first step of my production process is to log in the job on the log-in form, make a list of new artwork that has to be created, and either give that to the person that creates the artwork or sends it out to the digitizer. If I have to order anything for the project, I do so and put a copy of the original customer order in a plastic sleeve and hang it in the receiving area waiting for the goods to come in. A production form is filled out with the customer and job information on it that follows through the entire production process. The original order is placed into the customer's file folder in the office. I connect that order and the production form with the goods when they arrive.

After the design is ready, I place that with the order and it is then placed onto a shelf ready for hooping. If you have employees, it is best to have at least one job hooped ahead of time. This creates a smoother and faster production flow. When I had my large embroidery business, I have all of the jobs hooped the day before they were placed onto the embroidery machines. I had 24 dozen hoops of the most popular sizes (12 centimeters and 15 centimeters) so this was possible unless the order sizes were larger than 24 dozen. Sometimes this was the case, but at least the first 24 dozen pieces for the job were hooped ahead of time.

At the time for embroidery, the baskets of hooped garments are moved to the embroidery machine area and the machine operator can start the embroidery process. The design is loaded into the machine by whatever process you use to get your designs into the machine. The garment are then loaded onto the machine and embroidered. After they are embroidered, they are removed from the machine, unhooped and placed into another basket or bin and moved to the trimming area.

The trimmer will trim, steam, fold and pack the garments ready to be shipped. In a large business this will be more than one person. You will have a person that trims and steams and another one that will fold and pack the garments ready for shipping.

The production form is filled out by the operator with all of the information about each process as it passes through production.

Part 4 of Organizing Your Embroidery Business will be about shipping and invoicing procedures.

by The Embroidery Coach | | Organizing

In Part 1 of Organizing Your Embroidery Business, I talked about organizing your information that you use in running your embroidery business. In Part 2 I will talk about your customers design information.

I have all of my design or digitizing information in a separate drawer than I do all of the information that applies to the applications and how to run my embroidery business. This keeps a separation and keeps it a little more organized and not so confusing.

As far as paperwork and disks, I have always kept the disks that are applicable to the job in the same envelope as the paperwork. Today, for many machines and computers, the disks are now obsolete. In this case you must keep your designs in a customer folder on your computer using exactly the same name or ID number that you use on your customer design order form and design worksheet. All of your design information and blank goods information is kept in the same folder for the finished job.

After the job is completed, all of the paperwork that has been used and created to do the job is then placed into a catalog envelope along with the disk, if this is applicable, and filed by number into a file cabinet. In a small business, you can file them by alphabetical order, but this does not work in a larger one. In a larger business, you must file them by order or ID number in a file drawer by customer.

To save space and avoid file cabinets, all of the job information can be scanned and kept on your computer inside of the customer‚’s folder again by job number. When a re-order comes in, have all of the information printed out, placed in the job folder and connected with the garments and design ID number. I never have to guess on a re-order using this method of organization.

In Part 3, I will talk about the Production Organization.

In order to do this, you must sew out every embroidery font that you have available and know what the capability and size restrictions are for each one. This takes a lot of time and is totally unnecessary. Our customers get so confused when they are faced with so many choices. I have found that the best way to handle this is to offer 2 or 3 Block lettering styles and 2 or 3 Script lettering styles. This is enough for them to choose from and will prevent the customer from being overwhelmed with your vast selection.

In order to do this, you must sew out every embroidery font that you have available and know what the capability and size restrictions are for each one. This takes a lot of time and is totally unnecessary. Our customers get so confused when they are faced with so many choices. I have found that the best way to handle this is to offer 2 or 3 Block lettering styles and 2 or 3 Script lettering styles. This is enough for them to choose from and will prevent the customer from being overwhelmed with your vast selection.