We all need to start thinking about how we can prepare to make more money in the coming year! I have been working on my new marketing plan and during this time I have come up with 3 Tips that may help you as you are preparing to make more money in the coming year.

- Create A Great Mindset!

- Set Your Goals!

- Start The Year Off With All Of Your Financials In Order!

Create A Great Mindset!

This is the very beginning and most important tip of the 3. That is why it is No. 1.

Do you have a great or positive Mindset? Many times our thoughts, especially the negative ones, are what hold us back from succeeding at what we want to achieve and may really be hurting our chances of having a successful embroidery business. I thought that I had a positive mindset but I discovered that I had fallen victim to a negative mindset and it was all of my own self-talk and negative feelings.

I wanted to charge higher prices for my embroidery work when I first started my business but then the negative talk started. I had been told so many times that there was no way that I was going to be able to make a living with an embroidery business that I actually started believing it.

We second-guess ourselves and we have doubts when this happens. With all of the negative thoughts and other people‚’s opinions, we soon tell ourselves that we aren‚’t good enough, smart enough, talented enough, or whatever to be able to charge the prices we want or need to for our work. So we end up just settling for what we think we can get and really create a tough struggle for ourselves.

This was a huge struggle for me when I first started my embroidery business and it lasted for almost 15 years!I was determined to have the highest quality embroidery of anyone that I knew of that was in the embroidery business and I was told many times that I had accomplished that. I was offering this very high-quality embroidery at a price that was as low or lower than the embroidery businesses that were offering low quality. How stupid was that!

I thought that my customers would not pay the prices that I really wanted to charge and I found that the secret is not to project your thinking & feelings onto your customers! This mindset held me back for 15 years! Since everyone else was charging low prices, I thought that I had to stay in line with them or charge less to get the customers. That mindset almost cost me my entire business!

I did not realize that what I had to offer was a product that I could have priced much higher right from the beginning of my business but my mindset had blocked my ability to see that. It took my accountant practically batting me in the head to get this point across.

It was a struggle for me to change that mindset but with his help, I was able to do so. I guess you would say, he was my first business coach. When I changed my total mindset and started promoting my quality product and excellent customer service I had plenty of work! Most of my customers were already coming to me for my quality and service and when I raised the prices, they were OK with that.

I would love to be able to convince you and all embroiderers that you need to charge for your expertise. We are not or should not be struggling artists! We are highly skilled professionals and should be paid accordingly and you need to develop the mindset of a professional!

Set Your Goals For The New Year!

Now is the time to start thinking about the new goals for the coming year! This year is already half over and we need to be prepared to get the new year started off on the right foot! Are you on target to reach your goals this year? If not, how far are you from reaching them? What is the obstacle that is in the way that has prevented you from reaching your goals?

Sit down with a pad and paper and look back over each month of this past year and see where you were and think about what you could change to make this next year a more profitable year.

Now is the time to set your new goals for the coming year. Do not wait until January gets here. You need to get prepared months in advance so that you can start January off with the right plan to reach those goals.

Setting your goals is the very first step in creating your plan for the coming year. Do not set goals so high that you cannot reach them and do not set them so low that they do not mean anything. Set your goals a little out of your reach so that you do have to stretch in order to reach them.

Write down your Goals. I have found that if I commit to them on paper, not just on the computer, but actually writing them down they mean a lot more and I am more apt to follow through and reach my goals. You must create a plan for each one of your goals in order to be able to reach them.

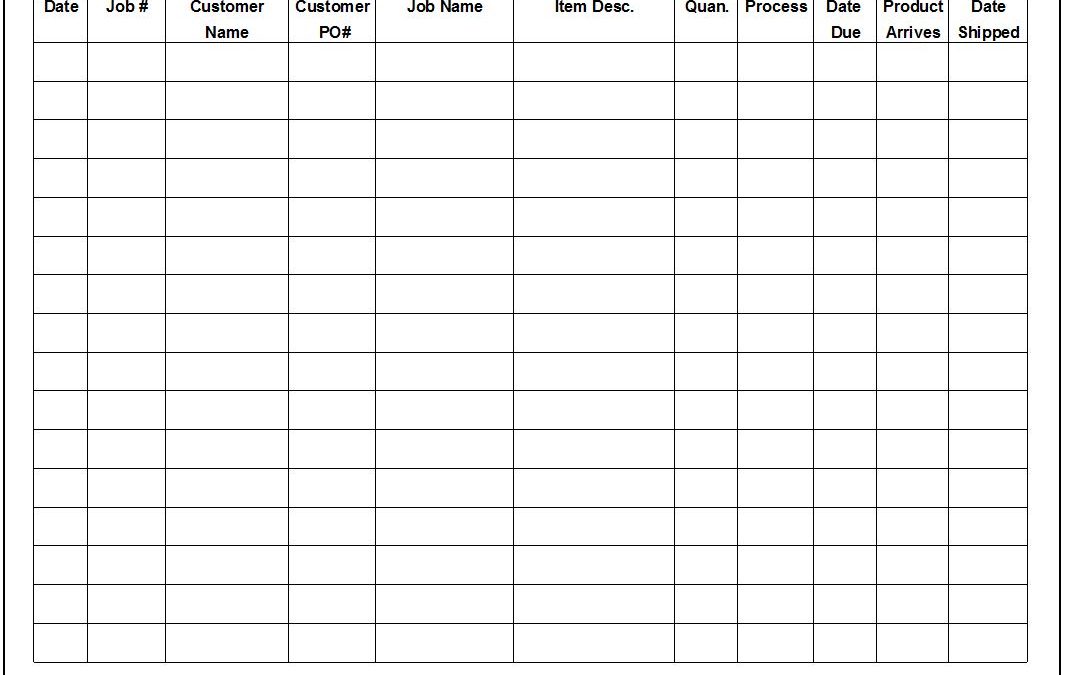

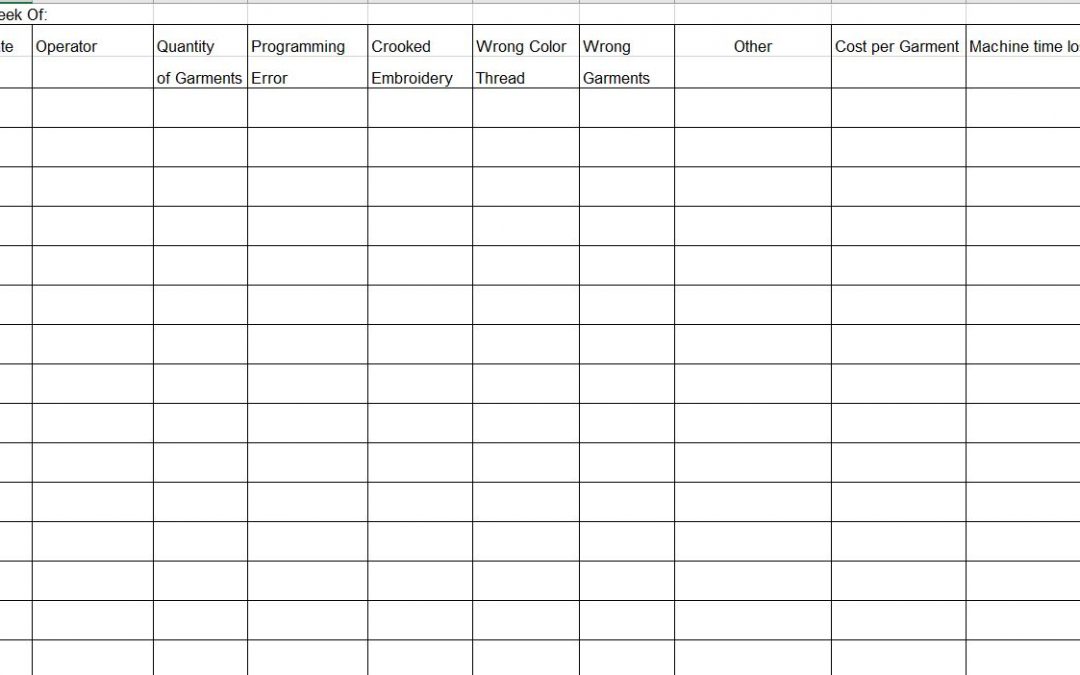

Start The Year Off With All Of Your Financials In Order

Do you know how where you will stand financially for your year end? I know that the year has not yet ended and we are few months away, but you should be able to anticipate how your year is going to end.

Are you happy with the results of where you are presently? Can you run off a quick report and see where you are today? You may or may not be happy with the way that your year is going to end or where you are today, but knowing exactly where you are financially is the first step in being able to make a change.

Without the knowledge of your current status, it is impossible to create a plan that is going to help you reach your goals and make the necessary changes in your business to do so for the coming year.

If you cannot run off a quick report to find out where you are, you need to start preparing to get all of your financials in order and be ready to start the new year going in the right direction. By the time the year ends, you need to have all of this information gathered.

- All of your expenses, month by month

- Your credit card purchases

- Your Bank Statements

- Loan information

Your next step is to see if you are making a profit. If not how far are you behind? Do you know your break-even point? This is exactly how much money you need to be bringing into your business each day, week or month in order to pay all of your bills, including a salary for you! You need to be rewarded for all of your hard work.

You need to know which area of your business is profitable and which area is not. This is the only way that you can realistically make the right course corrections and start your plan for next year. If you find an area in your business that is not profitable, get rid of it. It is not servicing you well and is costing you money.

Change your mindset, Set your goals and get your financials in order. This is the beginning of creating a great plan to help you make more money during the remainder of this year into next year!

If you will do some serious thinking about what I have given you in this article and start applying these tips, it will help you to get prepared for the coming year.