by The Embroidery Coach | | Embroidery Education

Many embroiderers find that embroidering Small Lettering is very challenging, but once you learn how to cope with many of the issues, it is easier. In order to control these challenges, there are some key elements that must be considered.

- Fabric

- Needles

- Thread

- Style of Lettering

- Underlay

The small lettering in the design, ONTARIO COUNTY, NEW YORK is only 3.6mm in height. This would not work well if it was upper and lowercase. It is best to keep lettering that small in all upper case letters. It also helps to use a plain block letter rather than one with serifs when you are embroidering lettering that small.

Making small lettering work to your satisfaction often means making adjustments to allow for your fabric type and the size and style of the lettering that the customer is requesting. Many times what they are requesting is not acceptable for embroidery. They are used to seeing their logos in type set usually in ink or screen printing ink and this does not always work with needles and thread. It is not uncommon for a customer to request an unreasonable amount of letters all to be placed on one line.

With Small Lettering, you have to create a balance between the fabric, needles, thread and the size and style of your lettering. You cannot have letters so small that you are creating stitches that will be stitching on top of each other. This causes holes in the fabric and thread breaks. Your stitch length must be a minimum of 1 millimeter in order for it to sew and not create holes.

Embroidering Small Lettering is not hard and you can learn to embroider small lettering on any type of fabric once you learn to control the factors that seem to make it difficult. Join us for the Small Lettering Intensive. Click on the link below for more information. Small Lettering Intensive.

by The Embroidery Coach | | Embroidery Business Marketing

The “Transformation Embroidery Business Blueprint” will help you Build a Wildly Successful Embroidery Business! Would you like to transform your embroidery business into one that is running smoothly, making great money, and lets you go home at night with a clear head? How would you like to stop those sleepless nights wondering if there was going to be enough money to pay the bills?

Here are 9 rules of the Transformation Embroidery Business Blueprint that will help you build a wildly successful embroidery business!

- Learn the skills to offer high-quality Embroidery. Make sure that every piece of embroidery that goes out of your shop is excellent!

- Deliver all of your jobs on time or ahead of schedule.

- Listen to your customers and give them what they want.

- Create a profitable Price List.

- Make sure your entire shop is organized and create Instruction Procedural Manuals (Standard Operating Procedures), for every area of your business so that your employees are highly trained, and you are all on the same page. If you have supervisors, they must be self-sufficient and highly trained as well.

- Have your Accounting Books set up properly and kept up to date.

- Create a Business Plan and a Marketing Plan that will help you stay on track.

- Market your embroidery business according to your Plan to reach your niche.

- Spend at least 30 minutes every day learning how to improve your skill level!

This is not hard to do. The bottom-line secret is to produce top-quality embroidery, learn how to price correctly, get organized, thoroughly train qualified workers, and stay on top of your books! It does take time to get all of these tasks accomplished. But when it is done, you can work less hours and be very happy with your business.

If you would like some guidance and help in transforming your embroidery business, I am here to help you get on the right track. Working less hours with the feeling of balance in your life is totally possible when you have implemented the “Transformation Embroidery Business Blueprint” that I have given you here. Being able to go home at night with a clear head is not only a goal but can become a reality. Wouldn’t it be great to not work weekends and holidays? You could be free to take family vacations without feeling guilty about not being at work.

Send me an email to joyce@theembroiderycoach.com and we can set up an appointment to give you a full business evaluation and help you get started right away. I’ll show you how to transform your embroidery business with a simple and practical process that will help you overcome any roadblock that stands in your way.”

My goal is for every embroidery business owner to be profitable and happy with their business. Use this Transformation Embroidery Business Blueprint to build a wildly successful embroidery business!

Remember, We Help Embroiderers Succeed!

by The Embroidery Coach | | Embroidery Business Management, Embroidery Production

Do you have the business organization and forms that help you to run your embroidery business? Do you have your embroidery business organized? When you first start your embroidery business you can become so overwhelmed by all of the forms and processes that are so necessary to keep your entire production running smoothly.

There are software programs that can be purchased to help you keep track of your entire order, but most new embroiderers are not in the position to be able to purchase these programs so you must have a way of keeping track of it manually. I always advise new embroiderers to start keeping track of their jobs manually before going to the computer systems.

Record keeping is so extremely important and there are many forms that I have and keep with each order. You must have a system for keeping track of each step and the forms for each part of your organization or production of every job. Without a good system in place, you will soon become totally overwhelmed with the workload and you will not be able to keep track of your production and it can become very discouraging. I have 3 types of forms

- Office or Sales Forms

- Production Forms

- Shipping Forms

The Office or the Sales Area is the First One That I Will Address.

This scenario is based on the fact that you are an embroiderer that sells retail and may have a retail or showroom in your location. If you are working from home and do most of your orders online or on the phone, the same processes and forms will apply to you as well.

I create sales packets that are ready for each sale so that I can grab them and be ready when I am first starting to work with a customer.

- Customer Quote Form – Can be part of the packet or separate-This form is filled out and a copy given to the customer-your copy is then placed in a binder until the customer comes back in ready to place the order.

- Order Form – I have one for Apparel and one for Caps-You can expand on this if you have different needs.

- Form of Payment -Credit card-Pay Pal-Check form

- Design Tracking & Timing Form

- Production Tracking & Timing Form

- Packing List

- Do you have a checklist to make sure that all of the steps are taken?

These ready-made sales packets make it easy to work with and you do not forget anything as you are going through the entire process with your customer or prospect. Between the Quote form, the Order form and the Form of Payment form, you can collect all of their information and be ready for the sales process. I also have all of their information to easily input it into my database and start marketing to them. This can be in the form of a Newsletter, postcards, emails or a combination of all three.

In the next post on do you have your embroidery business organized, I will go on to the next area of organization. Check out the free training that I will be having on August 3rd. https://theembroiderycoach.com/monthly-training/

by The Embroidery Coach | | Embroidery Business Marketing

Today I am going to show you the routine planning that I do every weekend using my Embroidery Business Planning Forms. I take Saturday morning to do my weekly planning but if something gets in the way, I will do it on Sunday afternoon. This helps to keep me on track and keeps my mind from wandering around trying to figure out what to do next. I always know what to do next!

Start Planning Small! If you have not been in the habit of monthly, weekly, or daily planning, you need to start today, but start small. I know that in all of the books about planning it says to start out with your entire year first, then your month, then your week, and then your day! To me, this was impossible when I first started my business. I could not relate to that because I really did not know what I was going to be doing in a year and I did not have any type of a plan in place.

I started by planning out my day at the end of the day before. I worked hard to try and complete what I had on my list to do. I also found out what I could realistically do in a day’s time. Once I got used to that and saw how much more smoothly my days started running, I planned out my entire week on a Master plan and then created the daily plan from there.

I have never found a planner that totally worked for me and I have been creating my own planning sheets for several years. Over the years they have changed and the set that I use now works out great for me. I will share those with you.

Now I have a basic plan for the year, but my Master Plan is mainly a plan for one quarter at a time. To me, that is much more realistic. I have specific goals that I set for each 90-day cycle and without my Master Plan, I would never reach them!

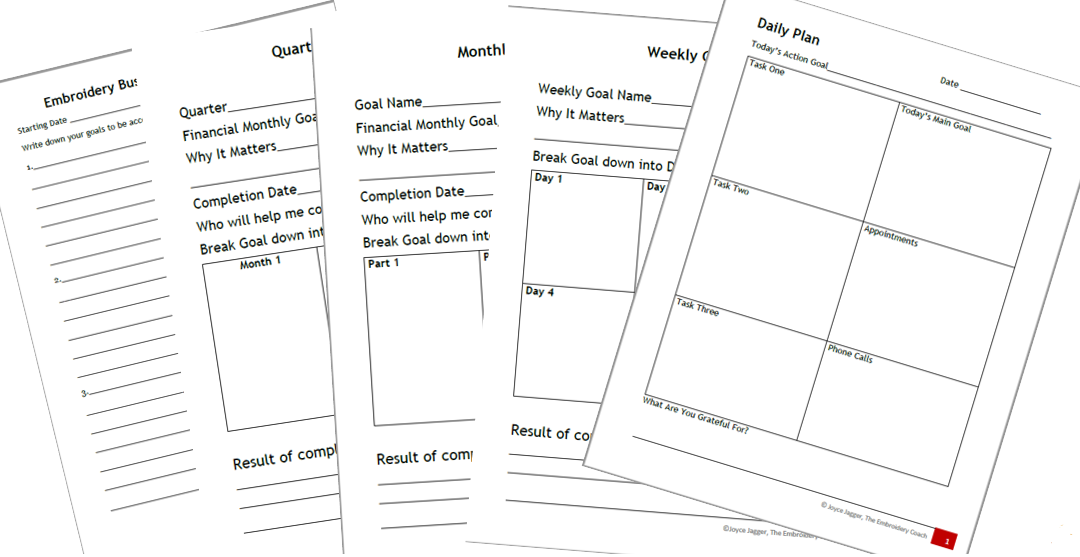

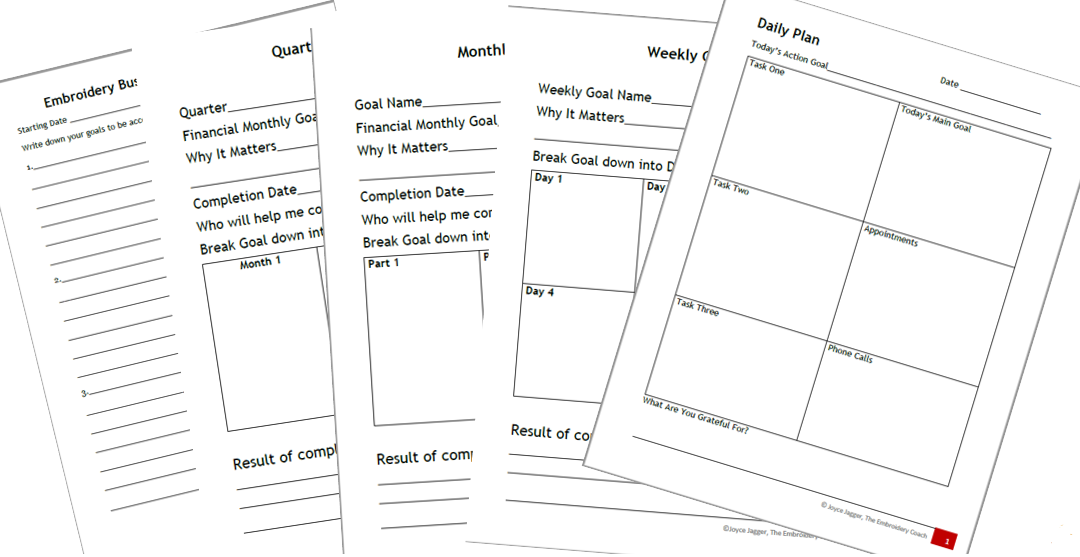

I have 5 sheets that I work with. I created them in a Word Doc and saved them as a .pdf and print out the set for each quarter, month, week, and day. I print out 6 pages for the week. I do not print one out for Sunday. I keep Sundays as free as possible. Saturday’s plan is usually personal stuff going on and not much business except for my planning.

Set of Embroidery Business Planning Forms

- Annual Plan – Print 1 Page

- Quarter Plan – Print 4 Pages for year

- Monthly Plan – Print 3 Pages per Quarter

- Weekly Plan – Print 4 Pages per Month

- Daily Plan – Print 6 Pages per week

You do not need to print out any more than you need for one quarter at a time. I only print out the Daily planning sheets when I need them on Saturday to start my weekly planning.

At the beginning of each quarter, I sit down and go over what I accomplished during the last quarter. Was I happy with what I accomplished and if not, what can I do to turn that around so that I can still accomplish my goals for the year?

Quarter Goal Sheet.

I figure out what I need to do during this next quarter to work toward my annual goal. I divide that goal up into 3 pieces, one part for each month.

Monthly Goal Sheet

I then add that Monthly Goal to the Monthly Goal Sheet and divide that up into 4 weeks. I look at everything that I need to do and add that to my sheet during the week that I will need to get that goal done.

Weekly Goal Sheet

I then add the 4 pieces to each of the 4 Weekly Goal sheets and figure out what pieces to get done during each of the 4 weeks.

Daily Plan

Now it is time to go over everything that needs to be done during that week and add them to each of the 6 Daily plans. This must include your personal and business appointments, tasks, and phone calls that you need to get done. Don’t forget to allow time to go over your finances and see where are you by the end of the week.

Friday afternoon is my time to go over my numbers. This is a very important time and should not be ignored. This also gives you an insight as to what you need to do the next week in order to get closer to your goal. If you will follow this system, you will find it much easier to plan and keep yourself on track.

If you would like my set of Embroidery Business Planning Forms, fill in the form below and I will send them to you.

by The Embroidery Coach | | Embroidery Business Marketing

Here we are, the beginning of the last quarter of this year is here. It just sort of snuck up on me. Are you prepared for this last quarter? I have to admit, I really was not. Get started planning for the 4th Quarter today. When I look back on the 3rd quarter, I really did not get as much accomplished as I wanted. I was working my plan but I had a lot of life sequences get in my way, but that really is nothing new!

Last weekend, I looked back on the 3rd quarter and started planning for the 4th quarter of this year. I have to really step up on it if I want to reach my goal for the year! Have you looked back on the 3rd quarter and figured out what you really did accomplish and what you did not get done that you had in your plan?

Let’s face it, we all want to have a business that we love! We all want to start each day with the feeling of I can’t wait to get started today! Your business is a very serious venture and if you do not plan it out and work you plan, you are just running a hobby and you would be better off doing something else with your time unless of course this is the kind of life that you want! For me, I want to know what I am doing and what I need to do each day of my week and month. I wake up each morning with my plan in place and I know exactly what I have to get done that day and I do whatever I can to get it accomplished.

Does it always happen, No, but I sure do work at it hard enough and try to get it all accomplished? Without a written plan, I would not know what I had to get done by the end of this day, week, or this month in order to reach my goal.

Here Are 3 Tips To Help Get Started Planning For The 4th Quarter Easier!

- Set Your Goals!

Do not set goals too high that you cannot reach them and do not set them so low that they do not mean anything. Set your goals a little out of your reach so that you do have to stretch in order to reach them. Write down your Goals. I have found that if I commit to them on paper, not just on the computer, but actually writing them down they mean a lot more and I am more apt to follow through and reach my goals. You must create a plan for each one of your goals in order to be able to reach them.

- Reach Out for Help!

I used to create my plans in cycles of 60 days, but I have decided that I am going to start working in the 3 months quarters to reach my goals and get everything done that I want to be done at the end of this quarter. I have to reach out for help. I have hired someone else to help me and have given them instructions as to what I need to be done. When you are the main person in your business and the only one running it, trying to get everything done is impossible. There are tasks that you can hire out to take some of the big burdens off of your shoulders. This may be simply having someone come in and clean your home for you periodically. It may be someone that can run errands for you. Before my husband retired, I had someone do small errands for me each week, like going to the post office and making my bank deposits. This freed up a lot of time for me. I also have someone that does all of my bookkeeping for me.

I found that this was one of the areas that was really bogging me down. I have heard embroiderers say, as soon as I get enough money to hire someone I will, and it will be easier. This is the wrong way of thinking. Thinking like that will not be productive for you and you will find that that day will never come. You cannot get ahead and do everything yourself unless of course you are just starting out and you do not have much work. Once the work starts coming in, you cannot afford to try and do everything yourself because some of the other areas of your business will suffer when you are trying to get your embroidery work done.

- Find Out Where You Stand Financially!

Before I hired a bookkeeper, I was always behind with my books and before I knew it, the year was half gone and I had no idea where I was. I did not know if I was making a profit or losing money. I had a vague idea and I knew what was in my bank account, but it was very frustrating for me not to know where I stood.

If you do not know where you are financially, it can really put your whole business in a tailspin and it is usually a downward spiral. You need to know where you are at all times so that you can make the proper adjustments to change whatever needs to be changed. You must also be willing to say NO! This is another area that is a hard one for most of us embroiderers! I know that is a hard one for me, but I have come to the conclusion that I cannot do it all, and what is not creating the most profit for me is gone! You need to know which area of your business is profitable and which area is not. This is the only way that you can realistically make the right course corrections.

Tomorrow I will show my Weekly Routine For Planning! It is very simple!