by The Embroidery Coach | | Embroidery Business Marketing

I want to share with you how to create a system for embroidering team names on jackets or shirts. This time-saving system that I came up with for embroidering team names on jackets or shirts is very simple and as indicated, it is a huge time saver! I take my list of names that I received from my customer and arrange my items in the same order as the names on the sheet.

I take the list of names and put it on my copier and increase them in size by 200%. After that, I will cut all the names apart on my sheet and then tape them to each item according to the size.

After that, I hoop all the items and then stack them in order according to how they’ll be embroidered and how the names are on my sheet because I don’t want any mistakes. That is in the exact same order that the customer gave them to me and that’s how I will be sending them back.

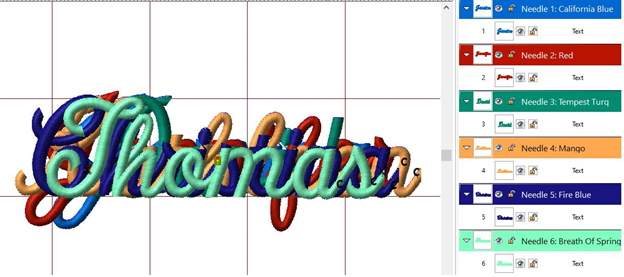

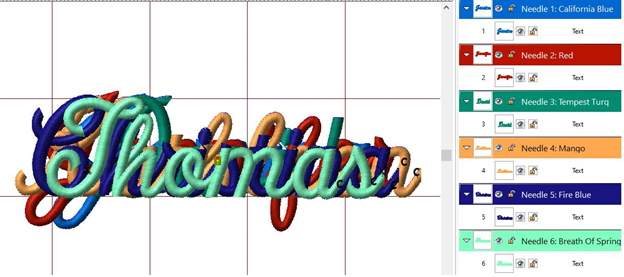

When I set up the names in my Pulse software, I set them up in a Name Stack. By that I mean I set up each name, put a color change between each one and then literally stack one name on top of another name in the software. This way they all start in the center and in the exact same place.

With the color change command between each name, I set the machine so that it automatically stops when it sees a color change command. When I put the first item into the machine and get it all set in place for the first name, it will embroider the first name and then stop.

This allows me the time to take out that first item and put in the next item on the list. I continue this until I am finished with the entire list of names. As the next one is embroidering, I remove the hoop, trim and stack the last one. I can embroider about 40 items in an hour on a single head machine using this method.

If you have a multi-head machine, you load the entire machine, again in the right order that the names will be embroidered, turn all of the heads off except head no. 1. Start the process with head no. 1 and when the first name is completed, turn off head no. 1 and turn on head no. 2 and continue this process until each one is completed.

You can create this system for embroidering names on jackets in any embroidery design software. It will work, trust me on that! No matter what I am charging, wholesale or retail this is a huge moneymaker! Try it, you will like it, I promise.

You can see how to go through the embroidery process inside of the Embroidery Business Academy in Skill Set No. 1. You will find it in Embroidery Production, inside of Embroidery Basics.

If you are interested in receiving this tip and a new one each day, Click Here!

by The Embroidery Coach | | Embroidery Business Marketing

In today’s world of rising prices and uncertainly, we need to be prepared to not only help our customers, but also make sure we can pay our bills! We are running a business, not a charity organization!

I was very excited about our new year and hoping that we could finally get back to normal and then we get hit with all of our supplies and the cost of freight going through the roof. What does that mean to us as far as our business is concerned?

It means that we have to raise our prices. You cannot absorb all of these costs. You must go into your pricing structure and make your adjustments for all of these price increases.

Ask yourself these questions:

- Am I paying more for the freight of my supplies?

- Am I paying more for the thread, bobbins, backings or stabilizers?

- Am I paying more for labor?

- Am I paying more for payroll taxes?

- Am I paying more for the products that I am ordering for my customers?

I have noticed a huge increase in every one of these. I am getting emails from my embroiderers complaining about all of this and what should they do? They keep telling me, “We are having a hard enough time trying to get people to pay our prices as it is, now we have to raise them? How can we do that and get in the job?” How can we stay in business?

Many embroiderers have gone out of business since the pandemic started, but many embroiderers have started businesses. The large companies that I work with have successfully raised their prices and are extremely busy. You have to do this too!

Embroiderers; everyone knows that you have to raise your prices. The price increases have hit every person on the planet, not just the embroiderers. Your customers understand that they are going to have to pay more for your services if they want to be able to promote their businesses!

Raise your prices! If you are having a tough time doing that or need some help with it, contact me. I have an excellent program that will help you get your Pricing structure together, one that will help you make money! Don’t put this off, get it done today before you end up having to close your doors!

by The Embroidery Coach | | Embroidery Business Marketing, Embroidery Education

Setting up the lettering to Embroider on the back of a mesh cap can be done very easily if it is done correctly. There is more than one way to accomplish this, but the way that you select will depend on the actual design that you plan on selecting or creating. Many embroiderers are afraid to try this, but if you follow the simple directions, I will try to make it easy.

If it is a text-only design, the small letters can get lost in the mesh and you will need to add a knockdown stitch under the lettering.

If it is a design that is a heavy complex fill design and no small lettering is outside of the area of the design, you can simply add a piece of topping to cover the entire area before you begin the actual sewing operation.

The Areas That I Will Cover In This Article

- The different ways you can create the lettering

- I am going to show you how to set up the lettering

- The process of creating the lettering

- Explain how to create the knockdown stitch

- Explain the settings I used and why I used them

I am going to show you how I set up the lettering to embroider on the mesh cap back using small text lettering only. The lettering that I will be using will be 6 mm or about 1/4 inch in height. I try to keep it to a simple block font that does not have serifs if at all possible. I also want to keep it in uppercase only, as this makes it much easier to read.

At that small size, a font with serifs does not work well because of the size of the serifs.

Different Ways To Create The Text Lettering

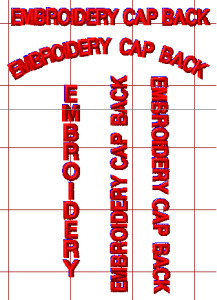

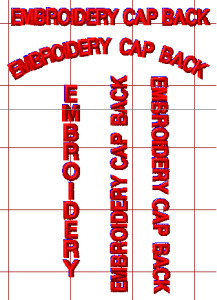

I have found that there are about 4 different ways that you could lay down the text lettering for the cap back.

- Horizontal for a straight bottom fitted cap

- Arched for a Snap-back keyhole cap back

- Vertical with the lettering starting at the top

- Vertical with the lettering reading up or reading down.

The Basics of Setting Up The Lettering

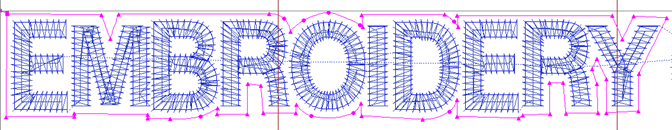

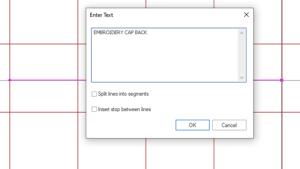

I used Pulse Embroidery Software to set up the lettering. I started with the basic Horizontal for the straight bottom fitted cap. The font that I used was Block New at 6mm.

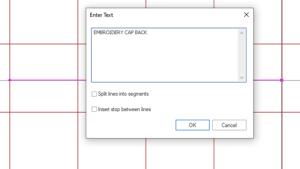

Step 1 – I selected my font, set it to 6mm, and then I drew a straight

line across the front of my workspace and typed in the lettering, EMBROIDERY CAP BACK. I then clicked OK and my lettering was on the workspace.

line across the front of my workspace and typed in the lettering, EMBROIDERY CAP BACK. I then clicked OK and my lettering was on the workspace.

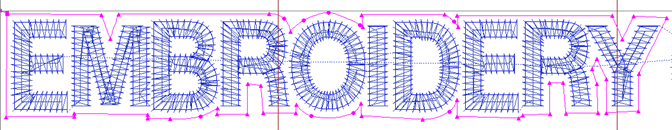

Step 2 – I added Center run Underlay Stitching at 1.5 mm in stitch length because the letters are so small and .20mm for the Pull Compensation settings.

Step 3 – I adjusted my spacing between the letters. You want to make sure that you have all of your settings in place and the lettering exactly as you want it before you add the knockdown fill on the design.

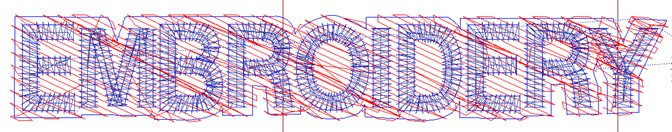

Step 4 – Zoom in on your lettering, turn off the 3D or TrueView of your lettering so that you see the stitch points on your letters.

You will notice that there is very little space between each letter. You want your stitch points to almost touch. This will give you a clean easy run on the machine without the machine adding locks and trims between each letter. You do not want your machine to stop and start between each letter, but you also do not want a thread showing between your letters when it is finished sewing,

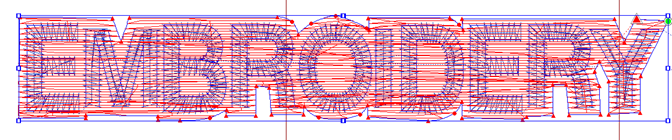

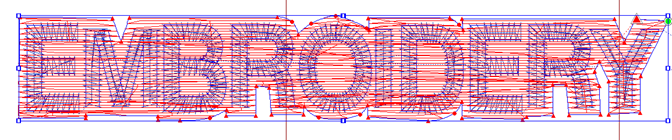

Step 5 – Create the Knockdown stitch. Pick up your Complex Fill tool in your digitizing tools and start plotting around the outside of the stitch points of your letters. You do not have to be perfect when you are doing this. You want it to be out and around the letters, but do not draw an oblong around the lettering, because it will show much more. You only want to draw around the shape of the letters.

This is what you will see when you have it completed. You would repeat the same process for the remaining 2 words before you go any further.

Step 6 – Now you must change the angle of the fill stitches so that your letters do not sink into the fill stitches and reduce the density to about -35 stitches per inch from your normal fill setting. I also added a .30mm pull comp setting to the fill. The image below will show your finished results.

Step 7 – In your Sequence View, move your fill background (knockdown stitch) up before the lettering so that it will sew out before the lettering sews. You will sew the fill stitching the same color as the mesh on the cap. When it is sewn out, you will hardly see the background stitching at all.

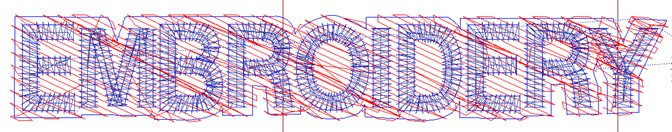

Here is a finished Embroidery on the back of a mesh cap. This is a vertical design up the seam of the back of the mesh cap. The fill stitching or knockdown stitch is sewn in white. You cannot see the fill stitching under the letters and the letters sew out crisp and clean.

Here is a finished Embroidery on the back of a mesh cap. This is a vertical design up the seam of the back of the mesh cap. The fill stitching or knockdown stitch is sewn in white. You cannot see the fill stitching under the letters and the letters sew out crisp and clean.

This same lettering could have been sewn straight across the back at the

Setting up the lettering to embroider on the back of a mesh cap is not hard, it just takes a few minutes and the finished result is amazing.

Click on the PDF to print out How To Set Up The Lettering To Embroider On The Back of a Mesh Cap You will be able to see the images much better.

by The Embroidery Coach | | Embroidery Pricing

How can I price my embroidery to make a profit? This is a question that I am asked on a regular basis. How can I price my embroidery to make a profit especially when other embroiderers are practically giving their work away? Some embroiderers say to charge $1 per 1,000 stitches; others recommend flat-rate pricing. I'm not sure which way to go. Some of the embroiderers in my area are undercutting me. Which kind of pricing will help me stay competitive and make a profit?”

One dollar per thousand may not be enough and yet maybe it will work for you, but this does not always work. Staying competitive is not the answer. You must find a way to make yourself stand out from the other embroiderers, not just be competitive. What is it that you can do better or more efficiently than the other embroiderers in your area? What do you do that is a little different? Do you offer a service that the other embroiderers are not offering?

You must create your own pricing structure. You cannot price according to the competition or what anyone else tells you to charge. You have to charge according to what your expenses are and then add on for a profit. Stop and think about this for a minute.

- Why did you get into business, to begin with?

- Didn't you think you could make some money offering your embroidery?

- Didn't it cost you quite a bit of money to start this business?

- Where did that money come from? Did you borrow it from the bank? Did you take it from your savings or your retirement plan?

- Now how are you going to get that money back unless you make a profit?

This is a process that takes time but you need to know exactly what ALL of your expenses are to begin this process. If you are a home embroiderer, you must also plug in a salary and home office expenses into this equation. If your machine is paid for, add a machine payment into those figures for future planning. After that figure is established, figure out how many hours a day you run your machine. You can only count the number of hours your machine is actually running if you are pricing by the stitch count! Your machine only makes money when it is actually running!

There are many factors that go into pricing besides just how long your machine is running. You also have to figure in how long it takes to prepare your garments for production, how long for finishing up the order etc? What about preparing the design? Are you setting it up for sending it out to be digitized? You need to charge for that time and the cost of having the design digitized. Did you have to create the artwork before you sent it out? These are all costs that you are incurring during the production process that need to be charged to the customer, not absorbed by you. Many embroiderers include this in their pricing. I have a pricing program available that will guide you through how to figure out your pricing.

Do not listen to what anyone else is telling you to charge. If you are not making a profit with your pricing, do not do the job. The embroiderers that are practically giving away their work will be out of business long before the embroiderer that is pricing to make a profit! This embroiderer will also be more respected!

Joyce Jagger

The Embroidery Coach

by The Embroidery Coach | | Embroidery Business Planning

Having your business well organized and planned out is very important and a must if you want to profit in your embroidery business! I want to share with you the 9 steps that it takes in planning for a successful and profitable embroidery business!

Before I get started, I want to ask you a few very important questions, questions that you need to think seriously about. I also want to tell you that at the end of this presentation, I will be sharing an opportunity with you that if you take me up on it, you will be able to get your business organized much quicker and will have all of the tools to work with in order to be able to do it more efficiently. This will be huge in being able to get your business set up properly and get you on the right path to profit in your embroidery business.

- About how much planning do you think do you for your business on a daily basis?

- Do you have a Business Plan, One that you can actually use to run your business?

- Do you have a Marketing Plan?

- Do you have Specific Goals for your business?

- Is your embroidery business on track for meeting its goals this year?

- Do you have a plan in place for the lean times?

- Do you have a plan for each area of your business?

And the most important question of all!

- Do you run your business or does your business run you?

Planning for your Embroidery Business is one of the most important functions that you can perform in your business. Every single area within your business needs a plan, not only the one in your head but one written on paper.

Without a plan in place, we wander aimlessly through our day taking care of whatever problem comes across our path. The phone rings, you handle that problem, a customer comes in the door, you take care of that person, the day goes by in just this manner and before you know it, the day is gone and you feel like you have accomplished nothing.

How do I know this, I have been very guilty of this. Before I started planning out my entire business, I just handled each issue as it showed up and hoped at the end of the month I had enough money to pay the bills! This is not the way to run a business!

Your business is a very serious venture and if you do not plan it out, you are just running a hobby and you would be better off doing something else with your time unless, of course, this is the kind of life that you want! For me, I want to know what I am doing and what I need to do each day of my week and month.

I wake up each morning with my plan in place and I know exactly what I have to get done that day and I do whatever I can to get it accomplished. Does it always happen, No, but I sure do work at it hard enough and try to get it all accomplished. Without a written plan, I would not know what I had to get done by the end of this week or this month in order to reach my goal.

If you have your goals set and your plan together it is much easier to get through your day. Crazy things happen at times that put a stumbling block in front of you, but you still try to get around that block! This is the time when you have to make adjustments

I Started With No Business Plan

You may have heard me talk about how I started my business with no plan. I had no plan of any kind! I would sort of plan out my next day but it was only a to-do list that usually did not mean much of anything. If it got through my to-do list, OK, if I did not, oh well, I just did not get it done!

I did not even know what a business plan was. It was not until I had to go to the bank to borrow some money that I found out about a business plan. I also found out that I could not borrow any money without a business plan. They also wanted a business plan that made sense, one that I was going to follow.

I went to the Small Business Administration because that is what the bank told me to do. This is where I started learning how to create a Business Plan. I also worked with my accountant to help me get through my first one. It was really tough for me and took a huge amount of time. They required that I do a ton of research and I had to create a lot of financial data for them. I had not even heard of most of the statements that they required that I create.

At that time, I had no accountant and was not at all familiar with all of the statements that they were talking about. They wanted 3 years of projections, 3 years of Cash Flow statements, A Balance Sheet, my current Income statement, What was that? I was clueless!

Going through this entire process prompted me to go to our local college and take accounting courses. I found them very interesting and I learned a ton about business that was totally foreign to me. I also took Business Law and Business Report Writing. I finally felt a little more qualified to run a business and I understood the 9 steps to profit in your embroidery business!

line across the front of my workspace and typed in the lettering, EMBROIDERY CAP BACK. I then clicked OK and my lettering was on the workspace.

line across the front of my workspace and typed in the lettering, EMBROIDERY CAP BACK. I then clicked OK and my lettering was on the workspace.