by The Embroidery Coach | | Embroidery Business Marketing

Do you ever make mistakes when you are embroidering your garments? Have you been faced with an item that a customer brought in and it was not replaceable? Unfortunately, everyone makes a mistake now and then, but you need to know how to save those expensive garments when mistakes do occur! Sometimes you have garments that cannot be replaced! It is very important to have the skills to be able to fix these mistakes just in case you have items that customers have brought in to you and you do not have any way of replacing these items!

If it is an item that can be replaced, you need to weigh in the cost of replacing the item, your time spent on repairing it and of course the time that it takes to wait for the item to be shipped to you. Would it be more cost-effective to purchase a new item instead of going through the process to fix it?

Sometimes it makes no sense to spend the time to do it. This is something that you need to determine. You need to keep track of how long it takes you to do a repair or fix a mistake. You must know what your actual cost is for each type of mistake.

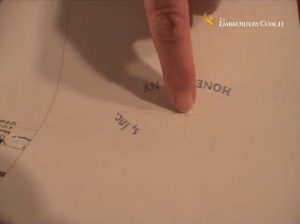

I have a 10-Step process to show you how to match up a design that has been taken out of the hoop before it was finished. This is a very common mistake especially if you are running a multi-head machine and you ran out of bobbin thread but the machine did not stop. In your haste to unhoop your items, you discover after it is done that it had not finished.

The mistake that I am going to show you is one that I hit the hoop with my arm and I just pulled the garment right out of the hoop. Now it needs to be rehooped and matched up perfectly so that the customer will not ever know that this happened. This is a very simple method that I learned many years ago and it works beautifully!

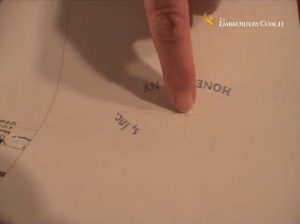

Step 1- Print out a copy of your worksheet from your design software. Make sure that you print out crosshairs or lines on your worksheet to make it easy to match it up in your hoop.

Step 2 – Cut out the design from the worksheet all around the edge of the design so that it matches the same size as  your finished design. You now have a paper pattern of your design. Look at it closely to get some good defining lines so that you can line it up perfectly.

your finished design. You now have a paper pattern of your design. Look at it closely to get some good defining lines so that you can line it up perfectly.

Step 3 –Cut out the first letter of this word and the last letter that was finished so that I can lay the paper but out

pattern down over top of the design on the shirt and line it up perfectly.

pattern down over top of the design on the shirt and line it up perfectly.

Place a piece of tape down to hold it in place.

Lift the edges of the paper pattern up it to make sure that the letters are in the exact same location.

Step 4- Place the bottom part of your hoop underneath your garment and position it to be in the center of your  design. Do not forget to place new backing on your hoop. Taping the backing around the hoop will help to hold it in place if you are not using a hooping device.

design. Do not forget to place new backing on your hoop. Taping the backing around the hoop will help to hold it in place if you are not using a hooping device.

I have a template with grids on it that I cut out from an extra one of my design placement templates. I lay it down on the horizontal and vertical lines of my design and line it up. With my grid, I can line up my design perfectly. If you do not have a grid that you can use inside of your hoop, you can mark vertical and horizontal lines from the edge of your paper pattern to the outer edges of where the design will line up with your vertical and horizontal lines in your hoop. I use a sharp edge of a piece of soap for marking my garments. Hotel soaps are great for this.

Step 5- Place the top part of your hooping frame on, line it up and press it down with the center lines of the grid  matching the center lines on the hoop both vertically and horizontally. If you are using marks that you made on your garment, they must line up perfectly in order for this to work, but it is not hard to do.

matching the center lines on the hoop both vertically and horizontally. If you are using marks that you made on your garment, they must line up perfectly in order for this to work, but it is not hard to do.

Step 6- Remove the template. The start/stop position of your paper design will be at the correct location in the center  of the hoop.

of the hoop.

Step 7- In your software, you will need to mark the start/stop position so that it stays in the center of your design

Delete all the parts of the original design that has been embroidered and is correct. Make sure to leave all of the part of the design that needs to be completed. This is now your new design.

Delete all the parts of the original design that has been embroidered and is correct. Make sure to leave all of the part of the design that needs to be completed. This is now your new design.

Save it with a new name so that you do not override your original design. Make sure that the new design is going to start in the same location as the original design.

Step 8- Place the garment into the machine and lined it up both vertically and horizontally. Remove the thread from  the needle to start with because you want to make sure everything is perfect and that it lines up with the last letter that finished.

the needle to start with because you want to make sure everything is perfect and that it lines up with the last letter that finished.

You have to hold the thread tight if you do not have a button to turn off the head because you don’t want it to register a thread break. Start the machine at a very slow speed or walk it holding the start button. This will help you make sure it’s lined up correctly.

Step 9- Stop, rethread the needle and remove the paper template and start the machine.

Step 10 – After the design is finished, you can pull it out of the hoop to see the finished product. If you follow this

method, everything matches and no one will ever know that you had made the mistake in the first place.

method, everything matches and no one will ever know that you had made the mistake in the first place.

I use this same method to repair many types of mistakes, such as when you must remove stitches and replace them. It works great for many different types of situations. It has saved me many times and keeps my customers happy! They never know a mistake was made in the first place!

For information on how to build a successful embroidery business, visit Embroidery Business Academy

by The Embroidery Coach | | Embroidery Education

Creating a simple system for storing embroidery information is very important. There is a lot of information available today and if you are like I was when I first started my business, you have collected everything that you could and put it in drawers or boxes to save until you could really study it. When I wanted to retrieve the information, I had no idea as to where it actually was. I spent hours going through all of my boxes to find a particular piece of information that I wanted.

I found through trial and error that the best way to save all of my information was to set up binders containing different subjects.

- Hooping

- Finishing

- Production

- Embroidery Design and Editing Information

- Maintenance

- Favorite Suppliers-with Addresses, Phone Number, Website with Login Info and your Customer Number for each.

- Resale Certificates for Dealers and Exempt Certificates for Organizations

- Quotes

- Pricing Information

- Price lists

- Customer List

- Best Selling Products List

As you collect your embroidery information such as an article from a magazine, cut it out from the magazine or copy it, punch three holes in it and place in the specific binder. You may need to create tabbed sections for different areas within that subject. When you print out files from TheEmbroideryTrainingResourceCenter or the EmbroideryBusinessAcademy, place them into the binders.

When you new Wearables or Impressions magazine arrives, sit down and quickly go thru the entire magazine. Cut out or copy each item that you want to save and immediately place it in the correct binder. Do not take the time to thoroughly read it. you can do that when you have the time or when you are looking for that type of information. Then throw out the rest of the magazine. You will soon have a complete reference system built up with all of your information at your fingertips when you need it.

As you grow you will need to create procedure manuals for each area in your business, but this is the beginning of creating a simple system for storing embroidery information. Make sure to sign up for our Free Embroidery Tips and add them to your binders!

by The Embroidery Coach | | Embroidery Education

Finding a good local digitizer is not so easy in today's market. The embroidery digitizing world has changed in the past few years and trying to find a good digitizer that is located here in the US is not really easy. With all of the competition from outside of the US, a digitizer from here cannot make a good living. What to expect from a digitizer for your embroidery designs is a very important question?

First of all, we all expect that the design that we have had digitized will come back to us perfect and the sew out will look just exactly what we had envisioned, but what happens when it does not? First we blame the digitizer for not coming through for us in exactly what we wanted, but did you give the digitizer all of the correct information to make this happen? What is the information that is necessary for the digitizer to give us that great design?

- What fabric is this design going to be sewn on?

- Will you be using this design for any other type of application?

- What format do you want the design to be finished in?

- Will you want to increase or decrease the size of the design from the original size?

- Does he have the liberty to make some modifications to the design to make it sew better such as increase the letter size or choose a different font style?

There can be many other questions, depending on the design and the information that you have given them. When you are looking for that perfect digitizer, look for one that uses the same software that you do and request that you have a copy of the outline or native file. This will allow you to make changes such as resizing or removing lettering from the digitized file. You may have to pay a little more for this privilege, but it is well worth it.

Digitizer must know embroidery production

Make sure that your digitizer knows production so that you have as few trims and color changes as possible. Make sure that he or she sews out the designs before sending them to you. This is a problem with a lot of digitizers, especially with Graphic Artists.. They get their software and think that since they can create any type of graphic art, they can digitize. This is far from the truth. They don‚’t usually know anything about the sewing process and have no idea about push and pull comps, underlay or density.

If you can find a digitizer that digitizes their designs using the same type of embroidery software that you are using, this is the best of both worlds. This makes it easier for you if there is need for a size change or some fabric setting changes. Instead of expecting that your designs are going to be perfect, it would be to your benefit to learn how to edit your designs so that you can get the perfect design that you are looking for.

Every embroiderer should take the time and make the investment in learning how to edit your designs that you receive back from the digitizer. If you have that skill lever, it is going to save you a lot of time and you will be able to make all of your embroidery designs production friendly! Your idea as to what you expect from a digitizer will change. You will not expect all of your designs to be perfect from the digitizer, and you will be more educated and be able to communicate better with your digitizer. This is going to give you a leg up from your competition!

by The Embroidery Coach | | Embroidery Business Planning

Having enough cash to run your embroidery business at times can be a real challenge but this is an area that you must stay on top of at all times. It is so easy to run on a day to day basis and forget how important managing your cash flow is to the overall health of your business.

Number One Way To Manage Cash Flow

The number one way to manage your cash flow is to get at least 50% down for each sale and collect the remainder on delivery or pickup of the finished product. This is the way that all Retail and Small Business accounts should be handled. Make sure you are making a profit on each sale.

Keep An Eye On Automatic Withdrawals

Do you have automatic withdrawals from your bank account? Stay on top of these to make sure that they are accurate and up to date. If the date that they are being withdrawn is causing you issues, ask your supplier to change the date to one that will better work for you. I found some programs on my statement that are no longer useful for me but the money was still coming out every month. If this is happening to you, cancel those programs. This one action alone resulted in $119.00 more per month in my bank account.

Keep Track Of Your Payments

Keep track of when your payments are due. If they are due in 30 days, and you do not have an early payment discount, pay them on the last day that they are due. This will keep you current wit your supplier and yet you can hold onto your cash as long as possible. Make sure that you pay them within the period that they are due to avoid having to borrow from your credit line or payment any interest on that payable.

Offer Early Payment Discounts

If you have contract accounts, make sure that they are current with their payments. If you offer them a small early payments discount, many will take advantage of it and pay early.

Create A Cash Flow Budget

Create a Cash flow budget or Cash Flow Statement that you will use on a daily basis. When you write a business plan you are required to write a Cash Flow Statement and many times it just stays with the business plan and never looked at again. Bad mistake! This Cash Flow Statement should be used and checked at least once per month to see if you are staying on track. If not make some adjustments.

Keeping a close eye on your cash flow or cash outflow will help to give you the cash that you need when an emergency arises or you find a special sale that you can take advantage of. Managing your cash flow can keep you in business much longer than just having a profitable business. A profitable business can go out of business just because they do not have enough cash to run with on a monthly basis.

Joyce Jagger

The Embroidery Coach

by The Embroidery Coach | | Embroidery Education

The question, Is it important to use Embroidery Underlay Stitching in my Embroidery Designs? is a question that is asked very frequently! Embroidery Underlay Stitching is important to use in all of your embroidery designs!

If you are new to embroidery or new to creating embroidery designs, learning the basic fundamentals of what makes a good quality finished design is extremely important. One of those basic fundamentals is Underlay. Many embroiderers do not use Underlay stitching because they have no idea how to use it or what type of Underlay to use for their particular design, stitch type or fabric style. Instead, they use a heavy density thinking that this will work but this can cause a multitude of problems.

Embroidery Underlay stitching is the most important and most underrated element of creating your designs. Like anything else that is built, you need a good foundation and Underlay Stitching is the foundation of your embroidery design. Many embroiderers are very confused and want to know:

- How can I tell if there is any Underlay Stitching in my design?

- What does it look like?

Underlay Stitches are the stitches that are sewn into your fabric first before the actual topstitching is sewn. If you are working with a design file, the .dst file extension, it is very hard for you to distinguish between the underlay and the topstitching.

Sometimes it will follow the same line as your embroidery and sometimes it will look very strange to you if you are new to embroidery and are not familiar with Underlay. It depends on what type of Underlay stitching the digitizer has chosen.

Embroidery Underlay Stitching has 6 basic functions.

- It attaches the garment to the backing creating a stable surface and smooth platform for the topstitching.

- It helps to reduce the amount of give in the fabric.

- It hides the color of the fabric that will be covered with stitching.

- It helps to reduce the density of the topstitching.

- It stops the fabric from puckering.

- It keeps the stitches from sinking into the fabric.

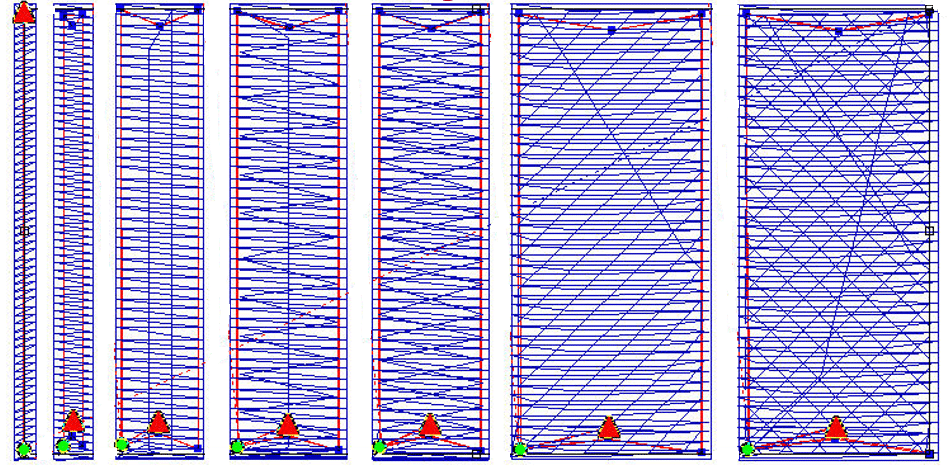

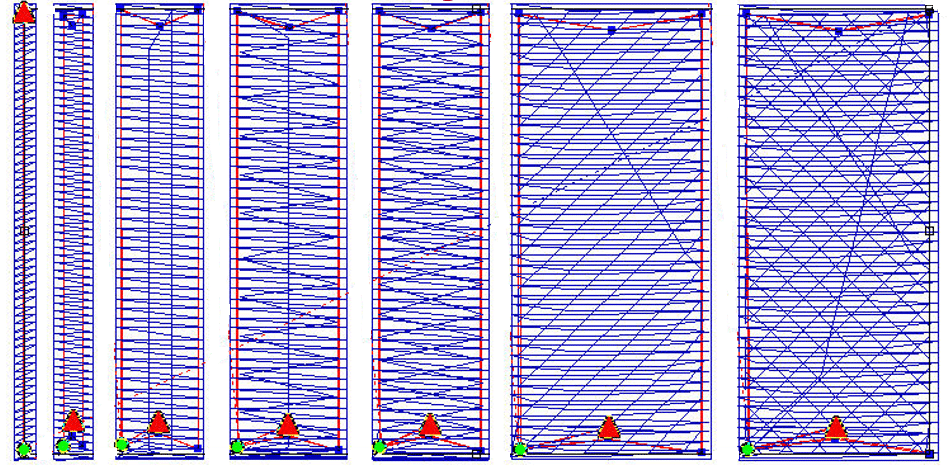

What are the different types of Embroidery Underlay Stitching?

There are 3 different stitch types that are used in creating underlay in your embroidery design.

- Run stitches

- Zig Zag stitches

- Fill or Tatami Stitches

These 3 different stitch types make up the 5 basic types of Underlay Stitches. These can be applied manually if you are digitizing your own design or they can be applied automatically if you have this capability within your software. Sometimes you cannot get the same effect using the auto functions in your software so you need to know how to apply the different types by hand so that you get the exact effect that you are looking for.

The Basic Embroidery Underlay Stitching Types Are As Follows:

- Contour or Edge walk – This creates a running stitch along the edge of the letter or the segment that you are creating. It is also known as an Edge walk stitch. This type of underlay is used to create a rollover edge for your lettering or object.

- Perpendicular or Center Walk– This underlay runs down through the center of the column. It is also called Center Run underlay. This underlay is used when you have a very narrow letter or column that is less than 1.5 m wide. For that, you will only use 1 line or pass of underlay down thru the center. This underlay is good to use in combination with contour or edge walk when you have a wider column and need a little extra for lift in the center of your column.

- Parallel– This underlay is created using Zig Zag stitches or run stitches. It travels only once down through a column. In some software programs, it is called the Zig Zag underlay. This can be used on a lightweight terry cloth or fleece.

- Zig Zag – This type of underlay is the same as the Parallel except it has twice the number of stitches. It runs down the column and then up the column creating twice the amount of stitches as the Parallel. In some programs, this is known as a Double Zig Zag. This is a better choice for terry cloth and pique. You may want to increase the density of your Zig Zag underlay to give your topstitching a puff or rounded appearance.

- Lattice or Tatami– This underlay is a low-density fill stitch used underneath Complex Fill stitches or Tatami stitches, depending on which embroidery design program you are working in. Lattice is usually used in combination with the Contour or Edge walk underlay. It runs at a 45 or 90-degree angle to the topstitching in a lattice form. It helps to reduce the pulling up of the fabric as it is stitching and to keep your stitches in good registration especially if you are going to add a border. It will help to keep the border in the proper place.

- Full Lattice or Double Tatami Stitches forming a full lattice effect going in both directions. This is a good choice if you are using a heavy contrast thread or fabric color such as a white thread on top of a black garment. This will hide the color of the fabric.

Very few designs or letters, even small ones are acceptable without underlay. Of course, there are always circumstances that change this rule. If you are working on a very lightweight fabric such as a wedding gown and you are using tone on tone, you may not want any underlay in certain areas especially if you are going to be seeing through the stitches. For this type of embroidery, you would not use any underlay at all but you would have to be careful that your stitch length was not too long because it would pull up and your garment would pucker.

I have created an entire program teaching you how to use the Embroidery Underlay Stitching properly. I even show you how to create your own underlay if you do not have the correct type in your embroidery design program. You can find that program at https://TheEmbroideryCoach.com It will teach you everything you need to know to add the right type of embroidery underlay stitching in your embroidery designs.

your finished design. You now have a paper pattern of your design. Look at it closely to get some good defining lines so that you can line it up perfectly.

your finished design. You now have a paper pattern of your design. Look at it closely to get some good defining lines so that you can line it up perfectly.

pattern down over top of the design on the shirt and line it up perfectly.

pattern down over top of the design on the shirt and line it up perfectly. design. Do not forget to place new backing on your hoop. Taping the backing around the hoop will help to hold it in place if you are not using a hooping device.

design. Do not forget to place new backing on your hoop. Taping the backing around the hoop will help to hold it in place if you are not using a hooping device. matching the center lines on the hoop both vertically and horizontally. If you are using marks that you made on your garment, they must line up perfectly in order for this to work, but it is not hard to do.

matching the center lines on the hoop both vertically and horizontally. If you are using marks that you made on your garment, they must line up perfectly in order for this to work, but it is not hard to do. of the hoop.

of the hoop. Delete all the parts of the original design that has been embroidered and is correct. Make sure to leave all of the part of the design that needs to be completed. This is now your new design.

Delete all the parts of the original design that has been embroidered and is correct. Make sure to leave all of the part of the design that needs to be completed. This is now your new design. the needle to start with because you want to make sure everything is perfect and that it lines up with the last letter that finished.

the needle to start with because you want to make sure everything is perfect and that it lines up with the last letter that finished.

method, everything matches and no one will ever know that you had made the mistake in the first place.

method, everything matches and no one will ever know that you had made the mistake in the first place.