by The Embroidery Coach | | Embroidery Business Marketing

Knowing which embroidery backing to use on a particular garment when you are getting ready to embroider your design will make the difference between turning out a mediocre product or a high quality finished product.

Backing is required to give the garment or piece of cloth more stability so that it can hold the stitches

Some people are under the impression and have even been told by other embroiderers or instructors that you do not need a backing if your garment is heavy such as a bag, cap or a jacket back. You will have a higher quality result with a finished design if you do use a backing.

Often if I have a garment such as a bag that is hard to hoop with backing, I will hoop it without the embroidery backing and slide a piece under the hoop when I put it into the machine. This applies only to very rigid fabrics. This will give it the stability and crispness needed for the finished product. It also gives you a piece of backing to rip against instead of your garment if you happen to make a mistake. And trust me from time to time, we all make mistakes!

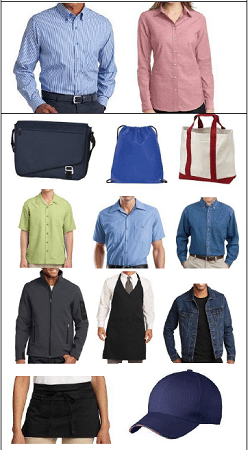

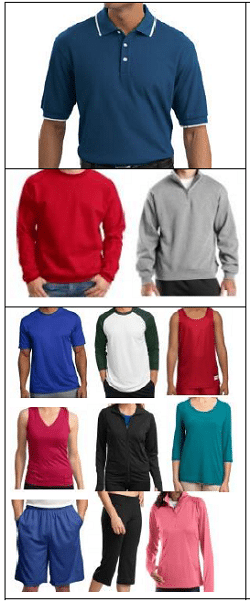

I am going to share some pictures of the different types of garments with you and this may make it easier for you to understand which embroidery backings to use on each type.

Two Categories Of Embroidery Backings

There are basically two categories of embroidery backings but within these two categories there are different types that you need to carry in your inventory to be used on a daily basis depending on what type of garment you are going to be applying your embroidery.

Knit Fabrics-Cutaway Embroidery Backing

Knit Fabrics-Cutaway Embroidery Backing

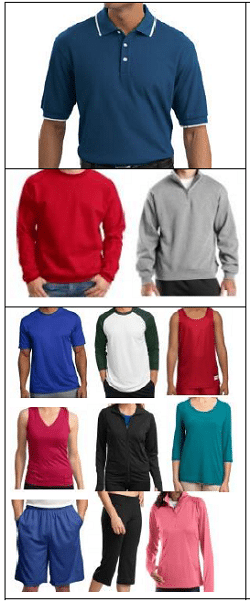

In the picture to the left you will see several types of knit garments. All of these garments should be backed with Cutaway backing.

There are several types of Cutaway embroidery backing but I am only going to be talking about 2 of them here.

Basic Cutaway backing is popular and is the most commonly used. It is awet laid non-woven embroidery backing designed specifically for machine embroidery. Available in several different weights; I recommend and use the 2 oz. backing for most of my applications. It can be used on all types of knits but I specifically use it on my heavier knits such as the left chest areas of Sweatshirts and Fleece .

No Show backing is a very light weight waffle weave cutaway embroidery backing used for all light weight and pastel colored knit fabrics. Sometimes it is called a Mesh backing. This is my favorite cutaway backing and it is so soft that it is advisable to use 1 layer of tear-away backing under it for extra stability especially if you have small letters in the logo.

The tear-away will then be torn off and the No show backing will be cut away. You will not see a shadow of the backing from the front of the garment as you so often see when using the normal basic cut-away backing. This is extremely important when you are applying your embroidery to the very thin fabrics such as the pima cottons or the performance wear fabrics.

The No show backing also works great if you are embroidering the full front of sweatshirts because it will let it fall in a natural manner instead of being stiff once the backing is removed. This type of fabric does not need the extra bulk of the two layers of normal cut away backing. Many people think because it is a sweatshirt, that you need to use heavy backing; untrue. It is stability you are looking for; not weight.

The combination of 2 layers of No show embroidery backing and 1 layer of 1.5 oz crisp tearaway backing works great for the moisture wicking or performance wear fabrics that are so popular today.

The No-show backing is a little more costly than the basic cutaway backing but to me the end result makes it well worth the cost. When I am trying to create a high-quality product, I need to use high-quality materials in order to produce that high-quality product!

Woven Fabrics Tearaway Embroidery Backing

Woven Fabrics Tearaway Embroidery Backing

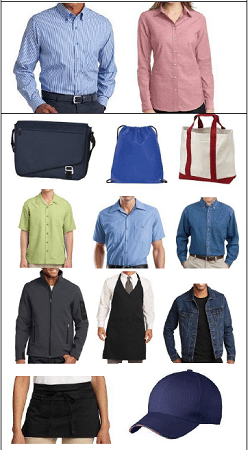

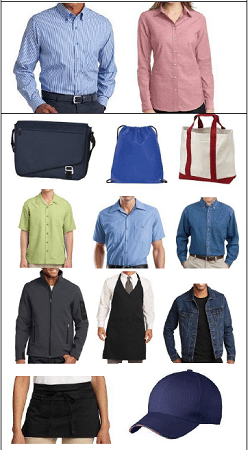

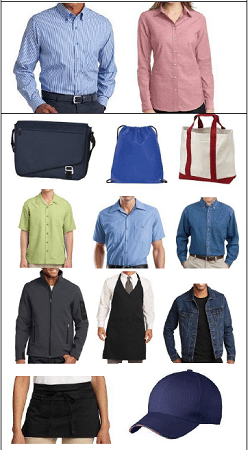

In the picture to the left you will see several types of woven garments. All of these garments should be backed with Tearaway backing.

Tear-away backing is used on all woven fabrics such as denim, chambray, twill, dress shirts, nylon oxford, canvas, bags, aprons, flags, sheets, pillowcases, tablecloths, napkins and etc.

It is also used on towels and washcloths. I have found that a 1.5 oz weight has worked best for almost all of my applications using the tear-away backing. I normally use two layers for most applications; sometimes I use only one and occasionally I will use three. I only hoop two layers into the hoop when I am hooping the garment, but I

will place another layer under the garment after I put it into the machine. This will give extra crispness to small lettering. It actually makes the columns in the lettering wider. It can also prevent puckering if the garment is hooped tight enough and has the proper amount of backing.

If you have a full back design that has several thousand stitches you will need a 3 oz. crisp tearaway backing. This 3 oz crisp tearaway embroidery backing is the same one that is used in caps, but it is on a larger roll rather than being cut in 4 inch strips.

Cap backing is a 3 oz. heavy tear away backing that is used on caps, front, sides and back. It usually is available in strips cut at 4 inches wide to fit inside of the front of caps. I have found that one layer of cap backing will work great for most caps, but sometimes if you have an unstructured cap 2 layers will produce a sharper more crisp look than using one layer. I will hoop one layer into the cap when I am putting the cap onto the cap frame, and then lay the extra layer into the cap as I am attaching the cap frame to the cap driver on the machine. It really does not take that much extra time and I notice a huge difference. The lettering will be much flatter and does not pull in nearly as much.

When hooping a cap back, I use a flat or tubular hoop and I do not hoop the backing in. I hoop the cap back, attach the tubular frame to the machine and then slide in a piece of the cap backing under the hoop. It really is too hard to keep the cap back straight when you are hooping it with the backing. I have also used cap backing at times as an extra layer on extra heavy terry towels. It really helps to flatten out the columns in the monograms. It will soften up after it is washed.

I hope that this helps to take the mystery out of which embroidery backing to use on the different types of garments. If you would like to have a copy of these Embroidery Backing Guides, fill in your Name & Primary Email address and I will send you a copy of each one.

by The Embroidery Coach | | Embroidery Business Marketing

The “Transformation Embroidery Business Blueprint” will help you Build a Wildly Successful Embroidery Business! Would you like to transform your embroidery business into one that is running smoothly, making great money, and lets you go home at night with a clear head? How would you like to stop those sleepless nights wondering if there was going to be enough money to pay the bills?

Here are 9 rules of the Transformation Embroidery Business Blueprint that will help you build a wildly successful embroidery business!

- Learn the skills to offer high-quality Embroidery. Make sure that every piece of embroidery that goes out of your shop is excellent!

- Deliver all of your jobs on time or ahead of schedule.

- Listen to your customers and give them what they want.

- Create a profitable Price List.

- Make sure your entire shop is organized and create Instruction Procedural Manuals (Standard Operating Procedures), for every area of your business so that your employees are highly trained, and you are all on the same page. If you have supervisors, they must be self-sufficient and highly trained as well.

- Have your Accounting Books set up properly and kept up to date.

- Create a Business Plan and a Marketing Plan that will help you stay on track.

- Market your embroidery business according to your Plan to reach your niche.

- Spend at least 30 minutes every day learning how to improve your skill level!

This is not hard to do. The bottom-line secret is to produce top-quality embroidery, learn how to price correctly, get organized, thoroughly train qualified workers, and stay on top of your books! It does take time to get all of these tasks accomplished. But when it is done, you can work less hours and be very happy with your business.

If you would like some guidance and help in transforming your embroidery business, I am here to help you get on the right track. Working less hours with the feeling of balance in your life is totally possible when you have implemented the “Transformation Embroidery Business Blueprint” that I have given you here. Being able to go home at night with a clear head is not only a goal but can become a reality. Wouldn’t it be great to not work weekends and holidays? You could be free to take family vacations without feeling guilty about not being at work.

Send me an email to joyce@theembroiderycoach.com and we can set up an appointment to give you a full business evaluation and help you get started right away. I’ll show you how to transform your embroidery business with a simple and practical process that will help you overcome any roadblock that stands in your way.”

My goal is for every embroidery business owner to be profitable and happy with their business. Use this Transformation Embroidery Business Blueprint to build a wildly successful embroidery business!

Remember, We Help Embroiderers Succeed!

by The Embroidery Coach | | Embroidery Business Marketing

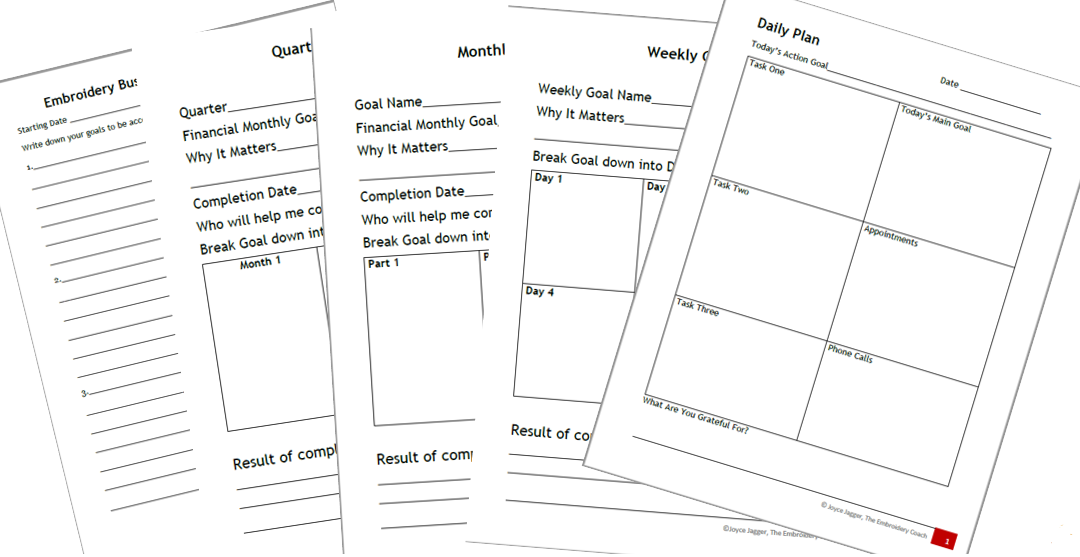

Today I am going to show you the routine planning that I do every weekend using my Embroidery Business Planning Forms. I take Saturday morning to do my weekly planning but if something gets in the way, I will do it on Sunday afternoon. This helps to keep me on track and keeps my mind from wandering around trying to figure out what to do next. I always know what to do next!

Start Planning Small! If you have not been in the habit of monthly, weekly, or daily planning, you need to start today, but start small. I know that in all of the books about planning it says to start out with your entire year first, then your month, then your week, and then your day! To me, this was impossible when I first started my business. I could not relate to that because I really did not know what I was going to be doing in a year and I did not have any type of a plan in place.

I started by planning out my day at the end of the day before. I worked hard to try and complete what I had on my list to do. I also found out what I could realistically do in a day’s time. Once I got used to that and saw how much more smoothly my days started running, I planned out my entire week on a Master plan and then created the daily plan from there.

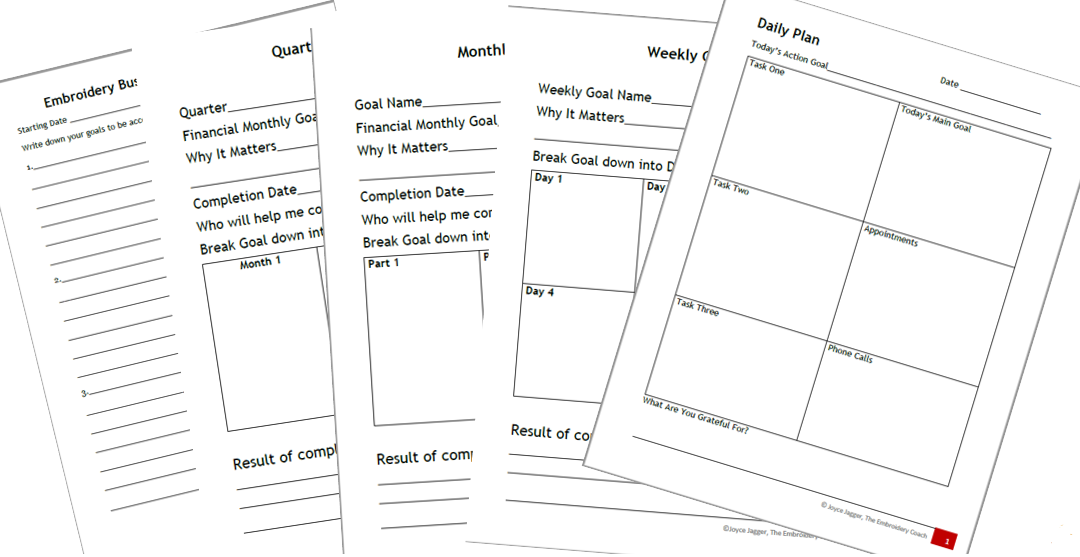

I have never found a planner that totally worked for me and I have been creating my own planning sheets for several years. Over the years they have changed and the set that I use now works out great for me. I will share those with you.

Now I have a basic plan for the year, but my Master Plan is mainly a plan for one quarter at a time. To me, that is much more realistic. I have specific goals that I set for each 90-day cycle and without my Master Plan, I would never reach them!

I have 5 sheets that I work with. I created them in a Word Doc and saved them as a .pdf and print out the set for each quarter, month, week, and day. I print out 6 pages for the week. I do not print one out for Sunday. I keep Sundays as free as possible. Saturday’s plan is usually personal stuff going on and not much business except for my planning.

Set of Embroidery Business Planning Forms

- Annual Plan – Print 1 Page

- Quarter Plan – Print 4 Pages for year

- Monthly Plan – Print 3 Pages per Quarter

- Weekly Plan – Print 4 Pages per Month

- Daily Plan – Print 6 Pages per week

You do not need to print out any more than you need for one quarter at a time. I only print out the Daily planning sheets when I need them on Saturday to start my weekly planning.

At the beginning of each quarter, I sit down and go over what I accomplished during the last quarter. Was I happy with what I accomplished and if not, what can I do to turn that around so that I can still accomplish my goals for the year?

Quarter Goal Sheet.

I figure out what I need to do during this next quarter to work toward my annual goal. I divide that goal up into 3 pieces, one part for each month.

Monthly Goal Sheet

I then add that Monthly Goal to the Monthly Goal Sheet and divide that up into 4 weeks. I look at everything that I need to do and add that to my sheet during the week that I will need to get that goal done.

Weekly Goal Sheet

I then add the 4 pieces to each of the 4 Weekly Goal sheets and figure out what pieces to get done during each of the 4 weeks.

Daily Plan

Now it is time to go over everything that needs to be done during that week and add them to each of the 6 Daily plans. This must include your personal and business appointments, tasks, and phone calls that you need to get done. Don’t forget to allow time to go over your finances and see where are you by the end of the week.

Friday afternoon is my time to go over my numbers. This is a very important time and should not be ignored. This also gives you an insight as to what you need to do the next week in order to get closer to your goal. If you will follow this system, you will find it much easier to plan and keep yourself on track.

If you would like my set of Embroidery Business Planning Forms, fill in the form below and I will send them to you.

by The Embroidery Coach | | Embroidery Business Marketing

Here we are, the beginning of the last quarter of this year is here. It just sort of snuck up on me. Are you prepared for this last quarter? I have to admit, I really was not. Get started planning for the 4th Quarter today. When I look back on the 3rd quarter, I really did not get as much accomplished as I wanted. I was working my plan but I had a lot of life sequences get in my way, but that really is nothing new!

Last weekend, I looked back on the 3rd quarter and started planning for the 4th quarter of this year. I have to really step up on it if I want to reach my goal for the year! Have you looked back on the 3rd quarter and figured out what you really did accomplish and what you did not get done that you had in your plan?

Let’s face it, we all want to have a business that we love! We all want to start each day with the feeling of I can’t wait to get started today! Your business is a very serious venture and if you do not plan it out and work you plan, you are just running a hobby and you would be better off doing something else with your time unless of course this is the kind of life that you want! For me, I want to know what I am doing and what I need to do each day of my week and month. I wake up each morning with my plan in place and I know exactly what I have to get done that day and I do whatever I can to get it accomplished.

Does it always happen, No, but I sure do work at it hard enough and try to get it all accomplished? Without a written plan, I would not know what I had to get done by the end of this day, week, or this month in order to reach my goal.

Here Are 3 Tips To Help Get Started Planning For The 4th Quarter Easier!

- Set Your Goals!

Do not set goals too high that you cannot reach them and do not set them so low that they do not mean anything. Set your goals a little out of your reach so that you do have to stretch in order to reach them. Write down your Goals. I have found that if I commit to them on paper, not just on the computer, but actually writing them down they mean a lot more and I am more apt to follow through and reach my goals. You must create a plan for each one of your goals in order to be able to reach them.

- Reach Out for Help!

I used to create my plans in cycles of 60 days, but I have decided that I am going to start working in the 3 months quarters to reach my goals and get everything done that I want to be done at the end of this quarter. I have to reach out for help. I have hired someone else to help me and have given them instructions as to what I need to be done. When you are the main person in your business and the only one running it, trying to get everything done is impossible. There are tasks that you can hire out to take some of the big burdens off of your shoulders. This may be simply having someone come in and clean your home for you periodically. It may be someone that can run errands for you. Before my husband retired, I had someone do small errands for me each week, like going to the post office and making my bank deposits. This freed up a lot of time for me. I also have someone that does all of my bookkeeping for me.

I found that this was one of the areas that was really bogging me down. I have heard embroiderers say, as soon as I get enough money to hire someone I will, and it will be easier. This is the wrong way of thinking. Thinking like that will not be productive for you and you will find that that day will never come. You cannot get ahead and do everything yourself unless of course you are just starting out and you do not have much work. Once the work starts coming in, you cannot afford to try and do everything yourself because some of the other areas of your business will suffer when you are trying to get your embroidery work done.

- Find Out Where You Stand Financially!

Before I hired a bookkeeper, I was always behind with my books and before I knew it, the year was half gone and I had no idea where I was. I did not know if I was making a profit or losing money. I had a vague idea and I knew what was in my bank account, but it was very frustrating for me not to know where I stood.

If you do not know where you are financially, it can really put your whole business in a tailspin and it is usually a downward spiral. You need to know where you are at all times so that you can make the proper adjustments to change whatever needs to be changed. You must also be willing to say NO! This is another area that is a hard one for most of us embroiderers! I know that is a hard one for me, but I have come to the conclusion that I cannot do it all, and what is not creating the most profit for me is gone! You need to know which area of your business is profitable and which area is not. This is the only way that you can realistically make the right course corrections.

Tomorrow I will show my Weekly Routine For Planning! It is very simple!

by The Embroidery Coach | | Embroidery Business Marketing

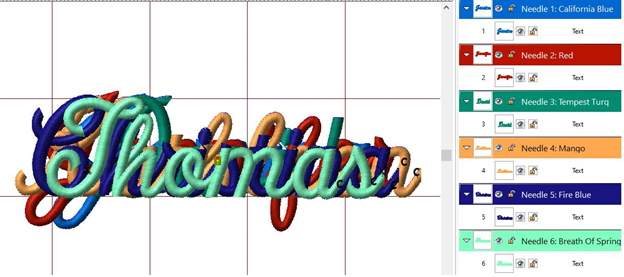

I want to share with you how to create a system for embroidering team names on jackets or shirts. This time-saving system that I came up with for embroidering team names on jackets or shirts is very simple and as indicated, it is a huge time saver! I take my list of names that I received from my customer and arrange my items in the same order as the names on the sheet.

I take the list of names and put it on my copier and increase them in size by 200%. After that, I will cut all the names apart on my sheet and then tape them to each item according to the size.

After that, I hoop all the items and then stack them in order according to how they’ll be embroidered and how the names are on my sheet because I don’t want any mistakes. That is in the exact same order that the customer gave them to me and that’s how I will be sending them back.

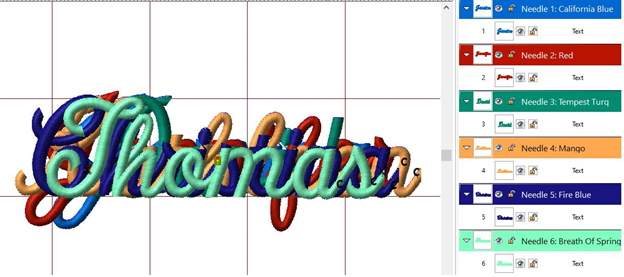

When I set up the names in my Pulse software, I set them up in a Name Stack. By that I mean I set up each name, put a color change between each one and then literally stack one name on top of another name in the software. This way they all start in the center and in the exact same place.

With the color change command between each name, I set the machine so that it automatically stops when it sees a color change command. When I put the first item into the machine and get it all set in place for the first name, it will embroider the first name and then stop.

This allows me the time to take out that first item and put in the next item on the list. I continue this until I am finished with the entire list of names. As the next one is embroidering, I remove the hoop, trim and stack the last one. I can embroider about 40 items in an hour on a single head machine using this method.

If you have a multi-head machine, you load the entire machine, again in the right order that the names will be embroidered, turn all of the heads off except head no. 1. Start the process with head no. 1 and when the first name is completed, turn off head no. 1 and turn on head no. 2 and continue this process until each one is completed.

You can create this system for embroidering names on jackets in any embroidery design software. It will work, trust me on that! No matter what I am charging, wholesale or retail this is a huge moneymaker! Try it, you will like it, I promise.

You can see how to go through the embroidery process inside of the Embroidery Business Academy in Skill Set No. 1. You will find it in Embroidery Production, inside of Embroidery Basics.

If you are interested in receiving this tip and a new one each day, Click Here!

by The Embroidery Coach | | Embroidery Business Marketing

In today’s world of rising prices and uncertainly, we need to be prepared to not only help our customers, but also make sure we can pay our bills! We are running a business, not a charity organization!

I was very excited about our new year and hoping that we could finally get back to normal and then we get hit with all of our supplies and the cost of freight going through the roof. What does that mean to us as far as our business is concerned?

It means that we have to raise our prices. You cannot absorb all of these costs. You must go into your pricing structure and make your adjustments for all of these price increases.

Ask yourself these questions:

- Am I paying more for the freight of my supplies?

- Am I paying more for the thread, bobbins, backings or stabilizers?

- Am I paying more for labor?

- Am I paying more for payroll taxes?

- Am I paying more for the products that I am ordering for my customers?

I have noticed a huge increase in every one of these. I am getting emails from my embroiderers complaining about all of this and what should they do? They keep telling me, “We are having a hard enough time trying to get people to pay our prices as it is, now we have to raise them? How can we do that and get in the job?” How can we stay in business?

Many embroiderers have gone out of business since the pandemic started, but many embroiderers have started businesses. The large companies that I work with have successfully raised their prices and are extremely busy. You have to do this too!

Embroiderers; everyone knows that you have to raise your prices. The price increases have hit every person on the planet, not just the embroiderers. Your customers understand that they are going to have to pay more for your services if they want to be able to promote their businesses!

Raise your prices! If you are having a tough time doing that or need some help with it, contact me. I have an excellent program that will help you get your Pricing structure together, one that will help you make money! Don’t put this off, get it done today before you end up having to close your doors!

Knit Fabrics-Cutaway Embroidery Backing

Knit Fabrics-Cutaway Embroidery Backing Woven Fabrics Tearaway Embroidery Backing

Woven Fabrics Tearaway Embroidery Backing