by The Embroidery Coach | | Embroidery Business Marketing

How Has The Pandemic Affected Your Embroidery Business? How has the pandemic affected you personally? Have you spent much time thinking about this and how you are going to make changes to be able to cope ? Do you know how to hang on to your embroidery business during these uncertain times?

Do you still have the same amount of business and customers that you had before the pandemic started? Have you noticed any attitude change in your customers and prospects? Are they giving you unreasonable requests?

I have heard a lot of embroiderers say that their customers are getting obnoxious and more demanding than ever. Some embroiderers are being treated like servants and are expected to continue to do more and work more and in today's' world they are being bullied into lowering their prices.

Are you wondering how you to deal with all of these situations right now? How should you hang on to your embroidery business? What you should do right now to hang on to your embroidery business and keep your customers coming back for more during these uncertain times?

No. 1 – PLEASE, do not get caught in this pricing trap. DO NOT LOWER YOUR PRICES to get the work! You will go out of business quicker than any thing. With the way that prices are increasing to all of us, you are going to have to raise your prices as well. We all have to pay our bills. All of our supplies and products that we have to purchase to do business with and resell to our customers are increasing in price and you cannot absorb those price increases. You must adjust your pricing and get your pricing structure created to work during this time.

No. 2 – Keep in touch with your customers. You want your customers to realize how important they are to you and how you value their business. Your customers are the lifeblood of your business and deserve your best. If you have not focused on your customer list and keeping in touch with them, stay tuned to my next post. I will explain how to get started with it so you can get that hang on to your embroidery business!

by The Embroidery Coach | | Embroidery Business Marketing

Recently, I was working with one of my Lifetime Students that was not sure how to price her embroidery. She had the misconception that the proven embroidery pricing program that I have created was not for her. She was a home embroiderer and thought that this program and the way that I teach you was only for big businesses! I was shocked! Do you feel like learning how to price your embroidery correctly seems to be too difficult or more advanced than what you feel you are ready for?

If that is the case, let me simplify this! Pricing your embroidery correctly, so that you can make a profit and not work quite so hard is comprised of 7 basic things.

- How much money you need to be bringing in every single day and then each hour of the day to pay all of the bills and give yourself a salary=Cost per hour

- Break this cost down into minutes

- How long each process in your business takes in minutes

- Knowing how much each process costs based on your minutes cost=Cost per process

- How long it takes to complete a job, from start to finish.

- What was that total cost?

- How much do you want to mark up your cost? (Min. 25%, I highly recommend 50 to 100% depending on the type of customer)

Basically, that is the total formula. Now that being said, it does not matter how long you have been in business, at what level of business you are, how many embroidery heads you have, whether you work from home or have a storefront, whether you have employees or not, whether you paid cash for your machine or borrowed the money. None of that matters. It all works the same.

Learning to price your embroidery is not difficult, but pricing must be done correctly so that you can in fact make a profit. but you may need some guidance in your circumstances to make it easier.

To make it easy, go to https://howtopriceembroidery.com. This simple program that will help you get your pricing together very easily. All you have to do is add your expenses and it will create your price list for you! Go to: https://HowToPriceEmbroidery.com You will be glad you checked it out!

by The Embroidery Coach | | Embroidery Business Marketing

Preventing possible issues with production runs is essential when planning your daily embroidery production. Trying to get the best production possible out of every single day is a must if you want a profitable embroidery business!

In today's economy, where so many embroidery business owners are doing all they can to keep expenses down with less employees, this is extremely important.

You always sew out all of your embroidery designs before you start any new jobs. Right!! Paying close attention to every detail of a logo is important when you are trying to prevent errors before starting a long production run! You want to thoroughly examine your design as it is stitching to see if there are any issues you need to correct or improve on.

You must watch the machine as it is sewing out your design in order to be able to pinpoint any of the possible problems! You cannot start the machine and walk away then expect to be able to find the issues, it just does not work. YOU MUST watch it as it sews out! As it is sewing out, ask yourself these questions:

- Is there something that you can do to shorten your run time?

- Are there any thread breaks? If so, find out why. Maybe your density is too heavy. Check for a dull needle, bad thread, or tension that is too tight.

- Is it locking as it starts and stops? If it does not lock at the beginning, the thread can come out of the needle. This can cause a real production nightmare! No lock at the end, the thread can unravel.

- Is it trimming where it is supposed to?

- Do I see any threads between my letters? If you do, they are not close enough.

- If I change my running order of my text will it run faster? First line left to right, second line right to left, third line left to right.

- Are all of the colors correct and are my colors running in the correct order?

- Do your letters or columns look to thick or too thin? Your letters may be pushing because your density is too heavy or your pull comp is too heavy. If too thin, your pull comp needs to be increased.

Check your sew out and have it verified before the job is started. Make sure that you watch each stitch as you sew out the design to see if there are any mistakes or problems that can be prevented. Slowing the machine speed down can help you pinpoint any issues.

- Do you have any jump stitches that are too long? This can cause the thread to get caught and your needle to break.

- Are all of your starts and stops in the correct location? If not, your machine has to move too far to start the next sequence causing wasted production time.

- Is your sew sequence in the right order? You do not want any travel stitches showing. A wrong sew sequence can create too many trims that could have been prevented if the sew sequence was changed.

- Can any of your color changes be combined? This will depend on how your design was created and what it is going to be sewn on. Sometimes like colors can be combined if your design is going to be sewn onto a flat garment. I do not recommend doing this for embroidery on caps. Please note: This can cause registration problems. Before you take this step, make sure that you can combine the colors and not have any registration issues.

It does not matter if you digitized your embroidery design or had the best digitizer out there doing your work, make sure that you sew out every design before you start the job and watch it sew out stitch by stitch. Not only will you prevent issues; you can also learn from watching your designs sew out. This is also true if you have set up a design or lettering in your software. Every design is a new design, digitized or not, and needs to have the same close attention to detail.

Create a checklist of all of the items to look out for as you are doing your sew outs and go right down that checklist to make sure that you have covered every item. This is going to help you save a lot of time and frustration as you are going through your long production runs.

There is nothing any more frustrating than having constant thread breaks or knowing that something could have been changed in your design to make the entire job get done in a lot less time! Time is precious and time is money! You cannot get it back once you have lost it!

It may seem like a waste of your time to watch designs sew out but it never is. I have been digitizing for many years and planning out production for many more years. I never send out a design to production unless I have sewn it out at least once to make sure that it has no issues, and yes, I watch it! Preventing unnecessary production issues is part of planning for all your embroidery production runs. This is going to help you create more profit in your bottom line!

Would you like a copy of the same checklist I use while sewing out each design? We will be happy to send it to you. You can pick one up for free by filling out this form.

by The Embroidery Coach | | Embroidery Business Marketing, Training Embroidery Employees

Do you have high-quality standards set in your embroidery business or are you focused on just getting the job done? Quality is extremely important if you want to build a business that is going to last no matter what state the economy is in.

Many customers are unaware of what good quality is when it pertains to embroidery. When you educate them and show them the difference, they get it. They also realize you want to provide them with the best!

I have certain standards that we have always gone by and if they are not met, the person responsible has to either be retrained so that they can produce the quality that I want or they will no longer have a job. If there has been a mistake on a job or if the job does not meet my standards of quality, I will not charge the customer for the job.

Case in point! We finished a set of 49 football jerseys that I was not happy with. While I was out training a new student, an operator embroidered the school name on the back of half of the jerseys instead of the front below the V of the neck where it belongs. I truly do not know how he ever made such a mistake, but it happened! These were $70.00 jerseys, which the customer supplied, before the numbers and embroidery were ever applied to them. This was an awfully expensive job, but I could not charge the customer for this. The mistake was rectified with the customer's help, but I could not in good conscience charge him for this job.

When I called him and told him about the problem, he was extremely grateful and happy that I was so honest about it. When I told him that I would not be charging him for the job, he was thrilled and said that they would live with the issue and that he would be sending me a lot more work!

If a mistake is made, do not try to pass it off on the customer without them being totally aware of it. Mistakes do happen to all of us, but you must own up to it, keep the customer informed, correct it, and in most cases let him make the decision on how to handle the job. It does not matter how large or how small the job is.

If you do not have high-quality standards set in your embroidery business, you will not stay in business for the long haul. This is especially important.

by The Embroidery Coach | | Embroidery Business Marketing

Do you ever make mistakes when you are embroidering your garments? Have you been faced with an item that a customer brought in and it was not replaceable? Unfortunately, everyone makes a mistake now and then, but you need to know how to save those expensive garments when mistakes do occur! Sometimes you have garments that cannot be replaced! It is very important to have the skills to be able to fix these mistakes just in case you have items that customers have brought in to you and you do not have any way of replacing these items!

If it is an item that can be replaced, you need to weigh in the cost of replacing the item, your time spent on repairing it and of course the time that it takes to wait for the item to be shipped to you. Would it be more cost-effective to purchase a new item instead of going through the process to fix it?

Sometimes it makes no sense to spend the time to do it. This is something that you need to determine. You need to keep track of how long it takes you to do a repair or fix a mistake. You must know what your actual cost is for each type of mistake.

I have a 10-Step process to show you how to match up a design that has been taken out of the hoop before it was finished. This is a very common mistake especially if you are running a multi-head machine and you ran out of bobbin thread but the machine did not stop. In your haste to unhoop your items, you discover after it is done that it had not finished.

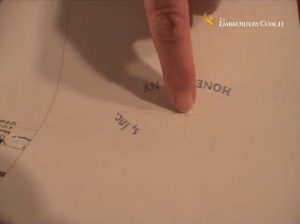

The mistake that I am going to show you is one that I hit the hoop with my arm and I just pulled the garment right out of the hoop. Now it needs to be rehooped and matched up perfectly so that the customer will not ever know that this happened. This is a very simple method that I learned many years ago and it works beautifully!

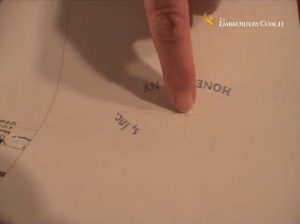

Step 1- Print out a copy of your worksheet from your design software. Make sure that you print out crosshairs or lines on your worksheet to make it easy to match it up in your hoop.

Step 2 – Cut out the design from the worksheet all around the edge of the design so that it matches the same size as  your finished design. You now have a paper pattern of your design. Look at it closely to get some good defining lines so that you can line it up perfectly.

your finished design. You now have a paper pattern of your design. Look at it closely to get some good defining lines so that you can line it up perfectly.

Step 3 –Cut out the first letter of this word and the last letter that was finished so that I can lay the paper but out

pattern down over top of the design on the shirt and line it up perfectly.

pattern down over top of the design on the shirt and line it up perfectly.

Place a piece of tape down to hold it in place.

Lift the edges of the paper pattern up it to make sure that the letters are in the exact same location.

Step 4- Place the bottom part of your hoop underneath your garment and position it to be in the center of your  design. Do not forget to place new backing on your hoop. Taping the backing around the hoop will help to hold it in place if you are not using a hooping device.

design. Do not forget to place new backing on your hoop. Taping the backing around the hoop will help to hold it in place if you are not using a hooping device.

I have a template with grids on it that I cut out from an extra one of my design placement templates. I lay it down on the horizontal and vertical lines of my design and line it up. With my grid, I can line up my design perfectly. If you do not have a grid that you can use inside of your hoop, you can mark vertical and horizontal lines from the edge of your paper pattern to the outer edges of where the design will line up with your vertical and horizontal lines in your hoop. I use a sharp edge of a piece of soap for marking my garments. Hotel soaps are great for this.

Step 5- Place the top part of your hooping frame on, line it up and press it down with the center lines of the grid  matching the center lines on the hoop both vertically and horizontally. If you are using marks that you made on your garment, they must line up perfectly in order for this to work, but it is not hard to do.

matching the center lines on the hoop both vertically and horizontally. If you are using marks that you made on your garment, they must line up perfectly in order for this to work, but it is not hard to do.

Step 6- Remove the template. The start/stop position of your paper design will be at the correct location in the center  of the hoop.

of the hoop.

Step 7- In your software, you will need to mark the start/stop position so that it stays in the center of your design

Delete all the parts of the original design that has been embroidered and is correct. Make sure to leave all of the part of the design that needs to be completed. This is now your new design.

Delete all the parts of the original design that has been embroidered and is correct. Make sure to leave all of the part of the design that needs to be completed. This is now your new design.

Save it with a new name so that you do not override your original design. Make sure that the new design is going to start in the same location as the original design.

Step 8- Place the garment into the machine and lined it up both vertically and horizontally. Remove the thread from  the needle to start with because you want to make sure everything is perfect and that it lines up with the last letter that finished.

the needle to start with because you want to make sure everything is perfect and that it lines up with the last letter that finished.

You have to hold the thread tight if you do not have a button to turn off the head because you don’t want it to register a thread break. Start the machine at a very slow speed or walk it holding the start button. This will help you make sure it’s lined up correctly.

Step 9- Stop, rethread the needle and remove the paper template and start the machine.

Step 10 – After the design is finished, you can pull it out of the hoop to see the finished product. If you follow this

method, everything matches and no one will ever know that you had made the mistake in the first place.

method, everything matches and no one will ever know that you had made the mistake in the first place.

I use this same method to repair many types of mistakes, such as when you must remove stitches and replace them. It works great for many different types of situations. It has saved me many times and keeps my customers happy! They never know a mistake was made in the first place!

For information on how to build a successful embroidery business, visit Embroidery Business Academy

by The Embroidery Coach | | Embroidery Business Marketing

Be Creative during the slow periods in your embroidery business is a great way to add new materials and do some extra planning that will bring in more sales. These slow periods are good times to develop new sales materials and samples. This is a time to be creative designing your new sales materials to use in marketing your embroidery business.

I embroidered new designs on white felt, cut out the design samples with pinking shears, and glued them onto card stock. I put these samples into 3 ring binders to distribute to my dealer customers during these slow times. I also embroidered all of the lettering styles that we offered onto the white felt using the standard thread colors that we had in stock. I labeled each lettering style the font name and the thread color. The dealers were always very impressed and thrilled to get their new sales materials from us. This was a way to showcase our work to our dealers and it gave them a way to show their customers the quality of work that they were offering.

I also embroidered coasters to give away as samples. I created a design with my logo, added my contact information and embroidered these on white felt. This is an excellent way to showcase your embroidery and a great leave behind when you are visiting a customer. This can be done for wholesale and retail customers alike.

You can also create new samples to give your showroom a fresh new look.

If you do not have any slow periods in your embroidery business, you need to block out some spare time to accomplish these little profitable, sales creating tasks.

Joyce Jagger

The Embroidery Coach

your finished design. You now have a paper pattern of your design. Look at it closely to get some good defining lines so that you can line it up perfectly.

your finished design. You now have a paper pattern of your design. Look at it closely to get some good defining lines so that you can line it up perfectly.

pattern down over top of the design on the shirt and line it up perfectly.

pattern down over top of the design on the shirt and line it up perfectly. design. Do not forget to place new backing on your hoop. Taping the backing around the hoop will help to hold it in place if you are not using a hooping device.

design. Do not forget to place new backing on your hoop. Taping the backing around the hoop will help to hold it in place if you are not using a hooping device. matching the center lines on the hoop both vertically and horizontally. If you are using marks that you made on your garment, they must line up perfectly in order for this to work, but it is not hard to do.

matching the center lines on the hoop both vertically and horizontally. If you are using marks that you made on your garment, they must line up perfectly in order for this to work, but it is not hard to do. of the hoop.

of the hoop. Delete all the parts of the original design that has been embroidered and is correct. Make sure to leave all of the part of the design that needs to be completed. This is now your new design.

Delete all the parts of the original design that has been embroidered and is correct. Make sure to leave all of the part of the design that needs to be completed. This is now your new design. the needle to start with because you want to make sure everything is perfect and that it lines up with the last letter that finished.

the needle to start with because you want to make sure everything is perfect and that it lines up with the last letter that finished. method, everything matches and no one will ever know that you had made the mistake in the first place.

method, everything matches and no one will ever know that you had made the mistake in the first place.