by The Embroidery Coach | | Organizing

In part 3 of this series on Organizing Your Embroidery Business I am going to be talking specifically about the Hooping Area and the tools and equipment that you need to be able to run that area efficiently in your embroidery shop.

In part 1 of this Organizing Your Embroidery Business series, I showed you a floor plan and in part 2, I talked about The Receiving area and what you needed to Process your Orders. Now we are ready to move to the next department in processing your order and that is Hooping.

For an efficient workflow in the Hooping department you need:

- Hooping Equipment

- Tools

- Supplies

Embroidery Hooping Equipment

In this article, I will talk about the Hooping Equipment and tools. You will need a Hooping Device and Embroidery Hoops or Hooping frames as they are sometimes called. Hooping can be done without a hooping device, but it is much quicker and more efficient to use one. You need to learn how to hoop without a Hooping device so that you know the basics of hooping. You will then be prepared for the times when a hooping device does not work for your particular situation. This happens quite often, depending on your garment and which type of hooping device you have.

Some of the Hooping devices will work with almost any size hoop such as the All in One Hooping device but others are specific to a sized hoop and you will need template inserts to use for each size hoop such as the HoopMaster.

If you have a large shop you may need a foot-operated hooping device. I have used all 3 types in my shop and have found each one to be very beneficial for the different types of hooping situations. In a large shop, you will need more than one device because you will need more than one person hooping the orders. It all depends on your workflow and how many embroidery machines you have in operation at one time.

If you are just starting out with your embroidery business a HoopMaster will be the best choice for you.

If you hoop a lot of caps, it is advisable to purchase the ‚ Third-hand Cap hooper. I purchased my first one in 1995 and I would not be without this hand-saving piece of equipment. If you are an older person or if you have a high-volume shop, this device is a must. It is easier to hoop caps and a lot faster using the Third-hand Cap hooper. It will pay for itself in a very short time and you will be so grateful that you made the decision to add this hooping device to your shop!

Embroidery Hoops or Hooping Frames

There are basic sizes and quantities that you need to keep in stock for your embroidery hoops or your hooping frames. The 12cm and the 15cm frames are the most widely used in this industry for most applications. I have also found that at least 6 hoops of each one of these sizes per head work best. If your budget will allow it, 12 per head is even better and more efficient. You can have your garment hooped ahead and the machine is never waiting for you to catch up. In order to make the most of your actual machine running time, you must keep it running as much as possible. You are not making any money if the machine is not in constant motion.

This is the list of the inventory that I have found to be necessary for a good workflow in a small home shop with two machine heads.

- 4 – 9 cm frames

- 12 – 12 cm frames

- 12 – 15 cm frames

- 4 – 18 cm frames

- 4 – 21 cm frames

- 6 – 30 cm square frames -12 in square

- 4 -270 Cap frames

- 4 -Large jacket back frames-whatever size that will fit your machine. Each machine requires a different size.

You can build your hoop inventory as you grow your business.

There are also clamping systems that make it easy for some hard-to-hoop items such as inside pockets of bags and inside of small areas.

Embroidery Marking Placement Tools

Necessary tools to keep on hand that will cover all of your hooping needs for marking placement are:

- Ruler

- Marking Grid

- Marking Tools

- Masking Tape

Marking tools are very important and necessary so that you can be consistent in your embroidery design placement. When you first start out you need to mark your first garment for placement using a Ruler or a Marking Grid. There are placement charts available and I furnish them to my students at the Embroidery Business Academy. These charts will give you the placement for most of your embroidery placement needs.

The tools that I have found that are the most useful for marking placement are:

- Chalk Pencil

- Air or Water Erasable Marker

- Soap

Soap is my favorite but you must be careful that it does not have any cold cream in it. I have found that the small soaps that I have picked up in hotels have worked the best, but again, do not use one that has cold cream in it. On some garments, this will leave a mark. I had this issue a couple of weeks ago. A dress shirt that had a Teflon coating on it was to be embroidered above the pocket.

The person that was hooping the shirt was new to hooping. She wanted to make sure that the embroidery was going to be straight above the pocket so she marked it and used a soap that in fact did have cold cream in it. Previous to now they had used that same soap on many fabrics without any type of issues. The finishing person wiped off the soap as normal but when she steamed the shirt it left a waxy marking line that would rub off.

As a general rule, the soap rubs off very easily on almost any type of fabric, but that was not the case with this teflon-coated fabric. After much rubbing, I was able to get that line removed. Another lesson learned, do not use a soap with cold cream in it. You must experiment with scraps to be sure that it will work on your fabrics.

The Air Erasable marker is great and was my favorite marking tool until I discovered the soap. You must be very careful though that you do not use the purple air or water erasable markers on red fabrics. Some of the brands will leave a blue line on the garment when you steam it. The purple ink in the marker reacts with the red dye in the fabric. This is also true for orange fabrics. You should not use these markers on any fabric that has red as its color base. For these fabrics use soap or a chalk pencil.

In part 4, I will talk about the supplies that you need and the actual process of hooping. After the garments are hooped they are placed in the staging area ready for the embroidery machine.

by The Embroidery Coach | | Organizing

In part 2 of this series on Organizing Your Business I am going to start talking specifically about the individual work areas or work stations within your embroidery shop. In this article I am going to start with the first area in your business after the order has taken. That area is Receiving.

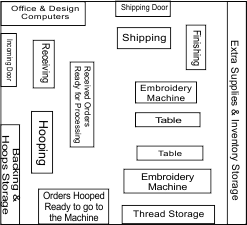

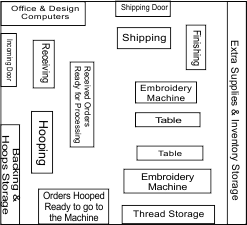

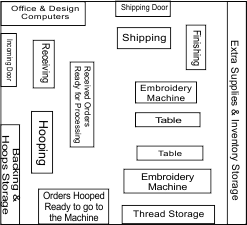

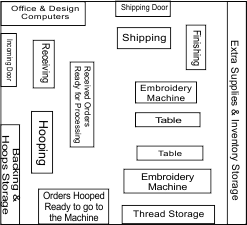

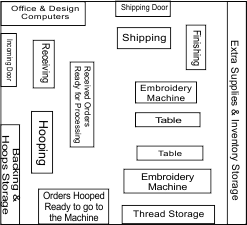

In part 1 of this Organizing Your Business series, I showed you a floor plan that is below on this page. This is a small shop with 2 embroidery machines and the square footage for this shop is about 1,000 square feet. I drew up this basic plan, but it is not drawn perfectly to scale. This plan was to show how you can lay out your shop for a good workflow and not specifically for an exact floor plan.

up this basic plan, but it is not drawn perfectly to scale. This plan was to show how you can lay out your shop for a good workflow and not specifically for an exact floor plan.

This is a basic floor plan that I had when I had a 6-head machine and 2 single-head machines. The single-head machines were sitting next to each other and in the floor plan, it is listed as one machine. At the time I had 5 employees, 2 machine operators, 1 hooper, 1 person finishing, and 1 person doing shipping & receiving.

It does not matter how large or how small your shop is, what matters is how you have it laid out and how many steps you are saving going from one area to another. Each one of your areas or workstations needs to be laid out in such a manner that it is physically easy for the person working in that area and efficient for the workflow.

One of the main concerns for employees is the table height that they are working at. It must be the right height for the person so that they do not have back aches and are not wasting time with the movements that are required for them to take as they are performing their tasks.

Received Orders Ready for Processing

Whether you have a large shop or a 1 person at home embroidery business, you must follow the same type of system in order to be efficient in your workflow. The first process that occurs after the order is taken is the Receiving of the order.

Your Receiving area needs to consist of a large table preferably with a back (like a short wall) built on it so that you have a place to hang your orders that are not complete in one form or another. The tools that you need for this area are a Copier or Computer and Printer and Plastic Job Folders for your orders. If you do not have a wall that you can hang the orders on, you can file them in a file box under your table.

As soon as the Order Processing is completed you are ready to Log in the Order. This is the first step in Receiving. You can Log the order in on the computer and then print out a copy daily and place it in a 3-ring binder. This binder will be stored on the Receiving desk. If you do not choose to Log in on the computer, you can create your Log in Form, print out the blank forms, and fill them in as the orders come in. If you are an embroidery shop where you have someone that receives the orders specifically, you can have them fill in the form as they receive the orders and at the end of the day, it can be input into the computer. This is the process for many small to medium-sized shops. The Login form should include the following information:

- Date (the order came in)

- Job Number

- Customers Name

- Job Name

- Item Description

- Quantity of Pieces in Order

- Process (embroidery, screen printing, twill, heat press)

- Date Due

- Date Goods Arrived from Distributor

- Date Shipped

The work order may come in from the customer by phone or email without the garments. If you are working with a Retail customer, you will be the one that is ordering the goods. The garments are shipped in separately from a distributor or manufacturer. Log the order in, assign it a job number and attach a copy of the order to a clipboard marked “Waiting for Goods”. When the Goods come in from the distributor or manufacturer, you pull out the Work Order and match it to the packing slip from the distributor. The order must match exactly.

- PO Number

- Quantity

- Item Number of the garments

- Color

- Sizes

You need to physically count all of the items and check to make sure that the color and sizes are correct and that there are no damaged goods. Notify the customer that the garments have been received and that there is a complete match or that there is a problem with the order and it is up to the customer to make whatever corrections there are to be made with the distributor or manufacturer. If it is for a Retail customer, you are the one that has to solve the problem with the distributor or manufacturer.

Design Work Can Begin As Soon As Job Is Logged In

After the goods have been successfully Logged In and even before the Goods are received the process for the design can begin. The design and sew-out can be done and approved by the customer while you are waiting for the Goods to arrive. Many times the entire job can be ready for production as soon as the goods arrive from the distributor. I will talk more about the design process in another article.

Once you have all of the information together and you have all of the correct items, place all of the information along with the order inside of a clear plastic Job Folder and tape it to the front of the box that has the goods inside of it. If there is more than one box label each box with the Order No., Job Name, and Box 1 of however many boxes in the order. It is now time to place the order in the Staging area of Received Orders Ready for Processing. At that point, the order can be picked up by the next person that is going to process that order. In the case of the Embroidery area, the next stop is Hooping. In our next article, I will talk a lot about the Hooping area. This is a big subject with lots of variables!

by The Embroidery Coach | | Embroidery Business Planning

Over the next few Ezine issues I am going to be sharing with you about how to “Create An Efficient Floor Plan and Workflow in your Embroidery Business.” In part 1 I am going to be talking about how to create a Floor plan that will give you a good work flow and not waste steps. One of the key elements to a highly profitable embroidery business is a good management system and part of that management system is a good work flow.

Setting Up Your Work Room To Create An Efficient Work Flow

Creating a blueprint for a good floor plan for your embroidery work room is one of the first things that should be done to insure that you will have an efficient work flow. A layout for the most efficient work flow should be done in a loop if at all possible so that each area is not conflicting with another area. In a good work flow the work runs efficiently from one production area to the next and without it, there are too many wasted steps from one job process to another. Below is a basic drawing of a small shop that has 2 embroidery machines. No work should be on the floor that is not in progress.

The workflow is as follows:

The workflow is as follows:

1. Order Processing

2. Receiving – Receiving should be located as close to the incoming door as possible.

3. Staging – Received orders waiting for the prep work and hooping.s

4. Prep – Where they are hooped and placed into baskets or bins ready to be transported to the embroidery machines.

5. Staging 2 – After they are placed in Baskets -Orders hooped ready to go to the machine.

6. Embroidery Machine – To be embroidered

7. Finishing – Where they are trimmed and packed. The Packed garments are then ready for Shipping.

8. Shipping or Picked up

If you are working from your home, your floor plan may be a little different and you may have only one door into your embroidery room. If this is the case, Shipping can be located in the same area as the Receiving, but on the other side of the area.

The best physical layout of your shop will determine how you will be able to place your embroidery machine for the best possible production. The most efficient layout I have found has been having tow machines across from each other with one side table in the center or two narrow tables in the center, one for each machine.

Another efficient way is a U shape having the third or smaller machine at the end of the U. In a single head shop or an in home shop, the prep area and Finishing area can be located on the same table directly across from the machine but keep your areas in different locations at each end of the table and you will be able to function more efficiently. The Prep area at one end and the Finishing area at the other end. If you have two machine, you can have them both across from table or one can be at one end of the table at the Prep area and one across from the table. It will depend on how large your room is and how it physically set up. Both layouts can be efficient.

Create A Blueprint Of your Embroidery Workroom Area

Before you start moving anything around, draw up a blueprint on a large piece of graph paper. Draw and cut out pieces of paper that represent the machines, tables and all other existing equipment. Draw these peices to scale so that it will work for you. Lay the marked pieces ont he graph paper and move each piece of the area that will represent where it should be moved.

Have every thread shelf, backing shelf or racks, hoops steamer, everything that you use that takes up floor space in these drawings so that nothing is missed. Once you have your layout exactly the way that you want it, take a glue stick and glue them into place. This will help you make sure that everything does get placed in the proper location when you do make your move. It will help everyone that is involved with the move be more efficient.

If any electrical or carpentry work is required, supply the contractor with a copy of the blueprint. This will help to explain exactly what is needed and will make it easier for everyone concerned. A well-organized floor plan is a critical factor when you are creating a highly efficient work flow.

The next article in this series we will about organizing each work area within your embroidery business. This is a very important aspect in creating a well organized business!

by The Embroidery Coach | | Embroidery Business Planning

I just received an article from my bank that would help you as you are learning how to control your cash flow in your growing embroidery business. If you are a one person shop some of this article may not apply to you, but now is the time for your to learn “How to Mange Your Cash Flow” and will help to give you the tools to be able to actually grow your embroidery business.

Many embroidery business go out of business because they lack the cash flow to keep them going especially during the tough times and to me this is very sad. I really hate to see this happen when it could be totally avoided with the right education and systems in place. Learning how to control your cash flow is a must if you want to stay in business and take your embroidery business to a level that will give you the profit that you are looking for in your business.

If you find this article helpful, please leave me a comment below. I would really appreciate it.

Joyce Jagger

The Embroidery Coach

by The Embroidery Coach | | Embroidery Business Planning, Embroidery Production, Organizing

In Part 1 of our Saving Time series I talked about how to save time Creating Embroidery Design Layout Style Sheets, in Part 2 I talked about Limiting Your Embroidery Lettering Styles and in Part 3 it was about creating Sample tags for all of your showroom embroidered product samples. Today I am going to go over how to create an Organized Ordering System.

An Organized Ordering System

An organized ordering system is simple to put into place. This is true when you have all of your information computerized and even if you are using paper forms to be filled out while you are waiting on the customer. You can create Sales Order Packets with all of your forms included so that you do not have to look for your information forms while you are working with your customer. Inside of this Sales Order Packet you should have:

- Customers Quote form

- Your Order Form

- Form of Payment

- Production Timing Form

- Artwork Production form

- Packing slip.

When you are first working with a customer, they usually want a quote before they place an order. Prepare your customers quote and make a copy of the quote form for him to take with him. Place your copy along with all of the other forms into a file marked Customer Quotes. When the customer comes back to place his order, pull the packet of forms from the quote file and you are ready to complete your order taking process.

By having all of these forms together in one packet, you will keep all of the customer information together and you will prevent mistakes from occurring.

During this series we have gone over 4 ways to help your customers make quick ordering decisions. You want the order process to be a pleasant experience for both you and the customer. When you offer your customers so many options they only get confused and it takes longer for them to make a final decision and sometimes that final decision is no decision. Reducing the amount of choices you have to offer will save you and the customer a lot of time.

I hope that this series has helped you to become a little more organized in your ordering process and that you see the value of taking the time to go through your ordering process and make some immediate changes that will benefit both you and the customer!

All of these forms plus many more business and production forms are available through my Embroidery Business Training membership website, the Embroidery Business Academy.

Joyce Jagger

The Embroidery Coach

by The Embroidery Coach | | Embroidery Business Planning, Embroidery Production, Organizing

In Part 1 of our Saving Time series, I talked about how to save time Creating Embroidery Design Layout Style Sheets. In Part 2 I talked about Limiting Your Embroidery Lettering Styles. Today I am going to talk about saving time by Creating Sample Tags with order information to apply to all of your showroom samples.

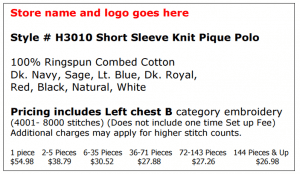

Sample Tags With Order Information

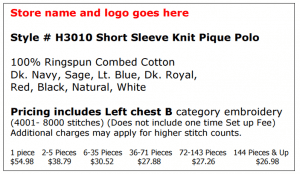

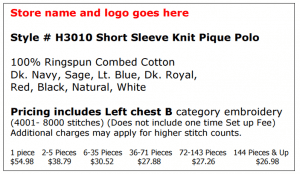

Your showroom should be complete with high-quality embroidery samples that are tagged with all of the order information that is applicable to that product sample. This tag should include the style number, colors and sizes available, manufacturer, price, and quantity pricing. All of this information should be on a Tag that is attached to the sample garment.

Your showroom should be complete with high-quality embroidery samples that are tagged with all of the order information that is applicable to that product sample. This tag should include the style number, colors and sizes available, manufacturer, price, and quantity pricing. All of this information should be on a Tag that is attached to the sample garment.

These embroidery Sample tags are very simple to produce and portray a good image to the customer about your organization. I created my Sample tags on card stock that I purchased from the office supply store, cut them apart, and laminated them. They stay very clean and always look professional when they are laminated. I then attached them with a Hang Tag attachment.

Having all of your samples tagged ahead of time with the appropriate information will save you a lot of time and prevent you from having to look up the information in the catalogs. As your pricing changes, so do your Sample tags. Always keep them up to date with all of the correct product and ordering information!

In part 4 of our Time-Saving series, I will talk about having an organized ordering system!

Joyce Jagger

The Embroidery Coach